Estimate the cost of operating labor (C OL ), the cost of utilities (C UT ), and

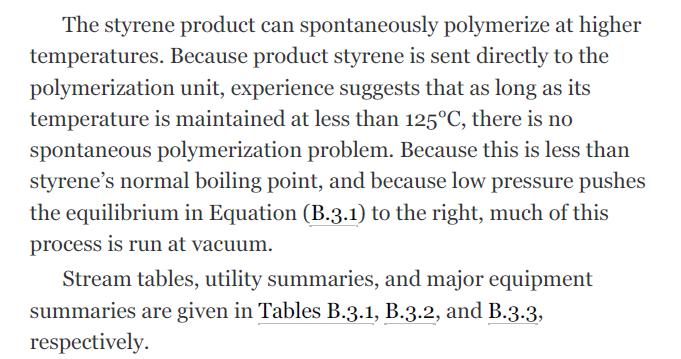

Question:

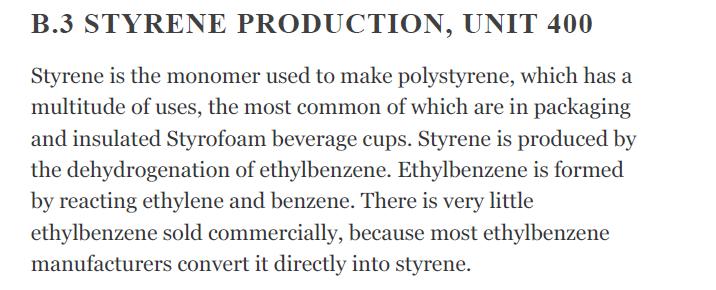

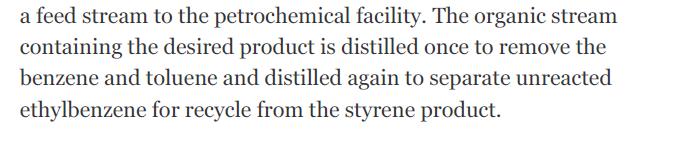

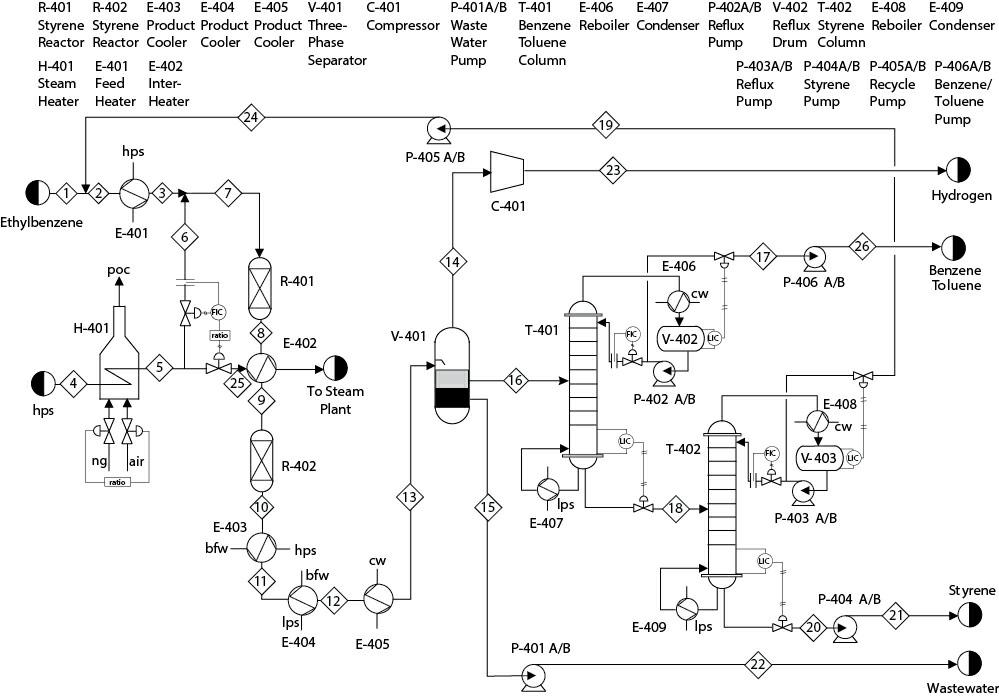

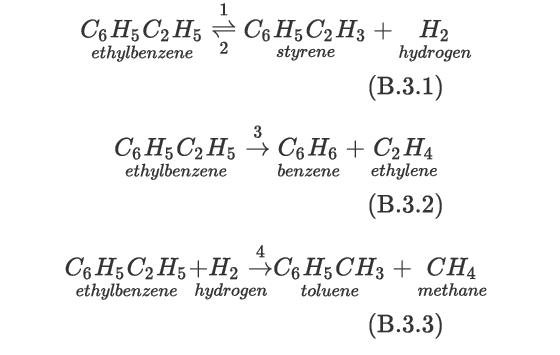

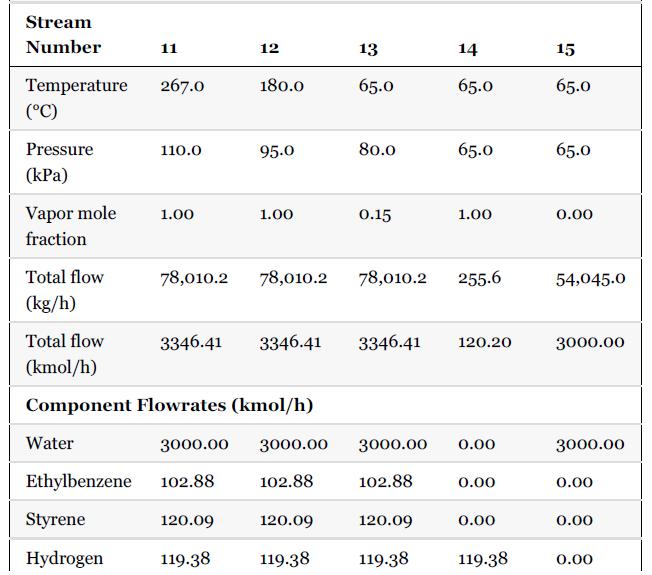

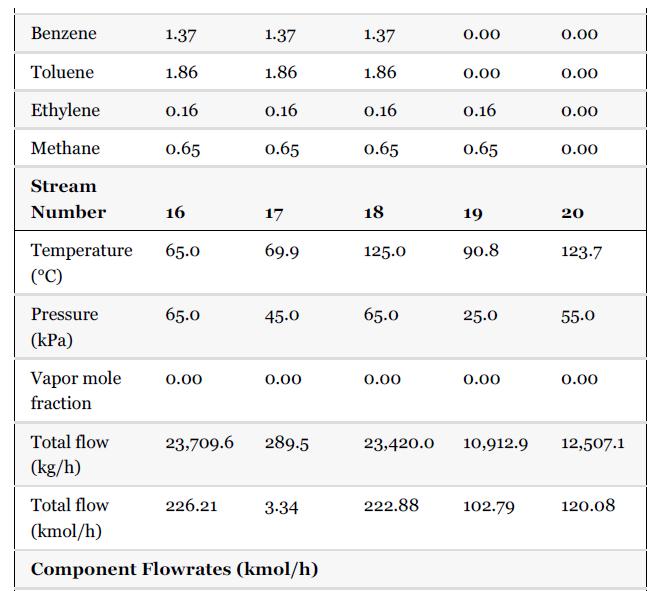

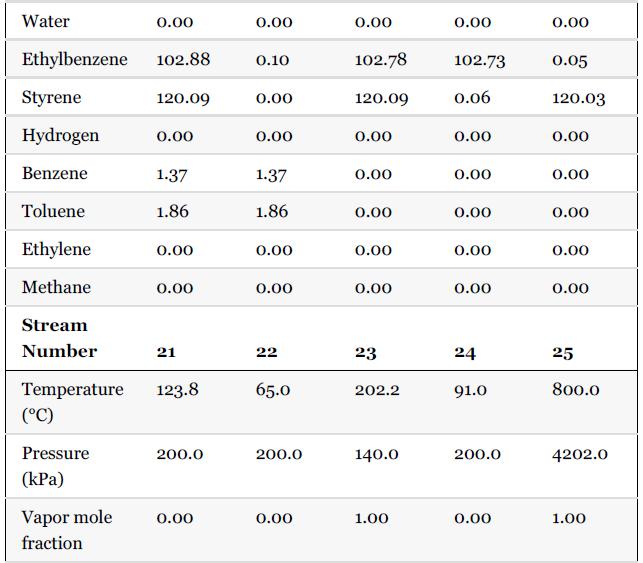

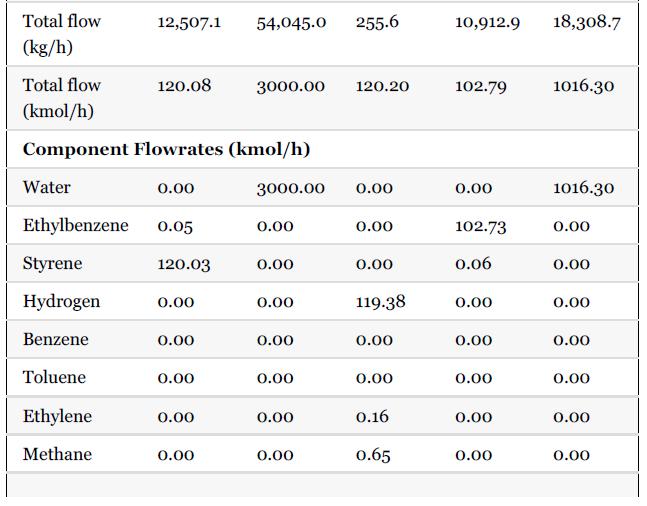

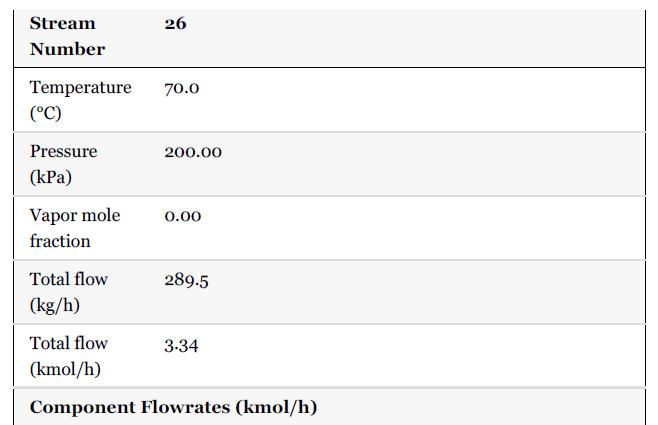

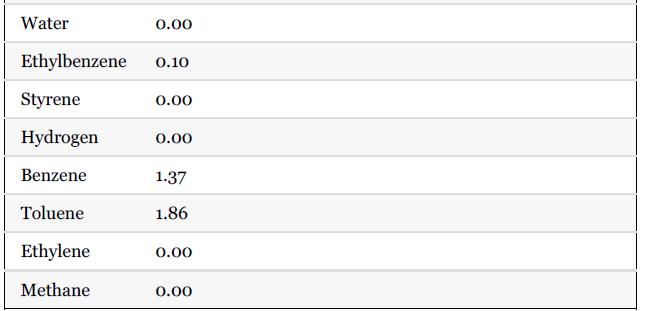

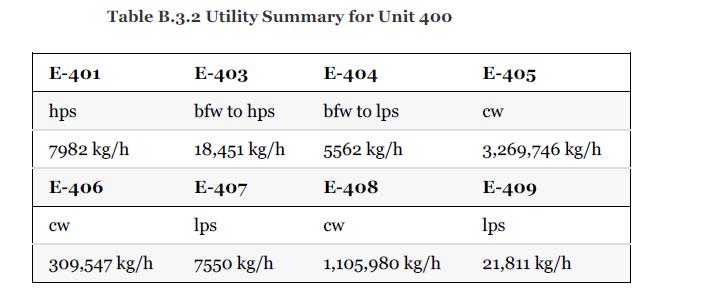

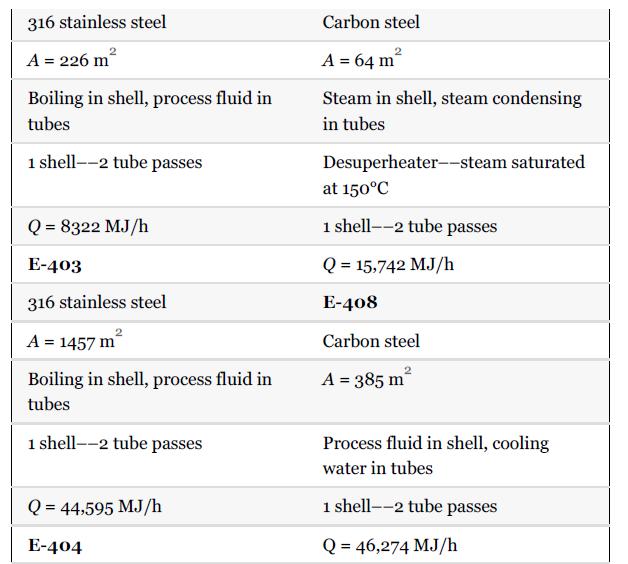

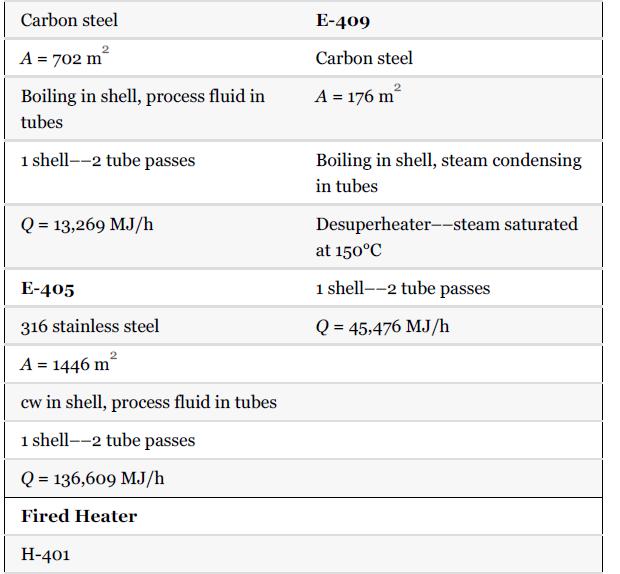

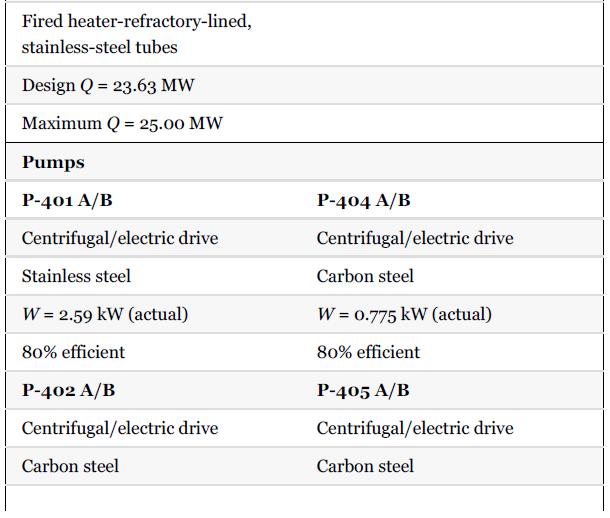

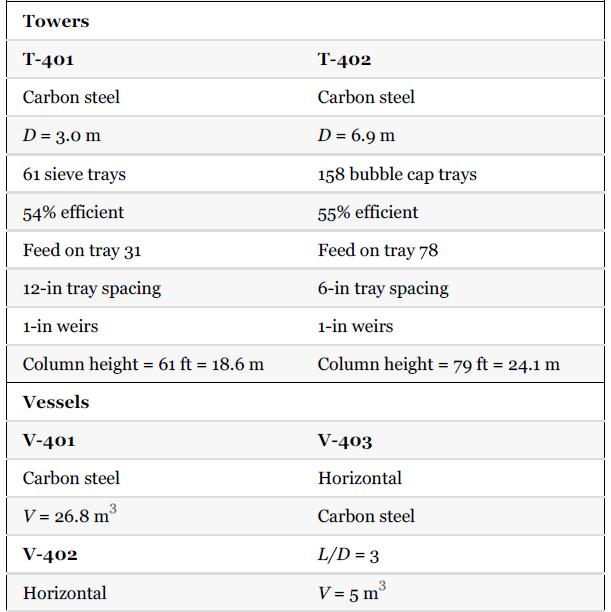

Estimate the cost of operating labor (COL), the cost of utilities (CUT), and the cost of manufacturing (COMd) for the styrene process given in Project B.3 of Appendix B. You must do Problem 7.23 in order to estimate COMd.

Problem 7.23

Determine the bare module, total module, and grassroots cost of the following:

Styrene plant described in Appendix B, Project B.3

![B.3.1 Process Description [1, 2] The process flow diagram is shown in Figure B.3.1. Ethylbenzene feed is](https://dsd5zvtm8ll6.cloudfront.net/images/question_images/1699/2/7/0/1896548ce2d9910d1699270187346.jpg)

Figure B.3.1

Fantastic news! We've Found the answer you've been seeking!

Step by Step Answer:

Related Book For

Analysis Synthesis And Design Of Chemical Processes

ISBN: 9780134177403

5th Edition

Authors: Richard Turton, Joseph Shaeiwitz, Debangsu Bhattacharyya, Wallace Whiting

Question Posted: