Maidwell Company manufactures washers and dryers on a single assembly line in its main factory. The market

Question:

Maidwell Company manufactures washers and dryers on a single assembly line in its main factory. The market has deteriorated over the last five years and competition has made cost control very important. Management has been concerned about the materials cost of both washers and dryers. There have been no model changes in the past two years and economic conditions have allowed the company to negotiate price reductions in many key parts.

Maidwell uses a standard cost system in accounting for materials. Purchases are charged to inventory at a standard price with purchase discounts considered an administrative cost reduction. Production is charged at the standard price of the materials used.

Thus, the price variance is isolated at time of purchase as the difference between gross contract price and standard price multiplied by the quantity purchased. When a substitute part is used in production rather than the regular part, a price variance equal to the difference in the standard prices of the materials is recognized at the time of substitution in the production process. The quantity variance is the actual quantity used compared to the standard quantity allowed with the difference multiplied by the standard price.

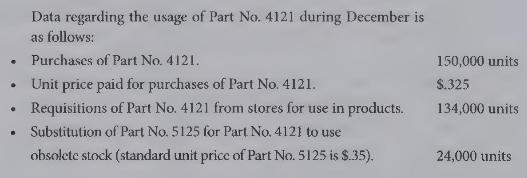

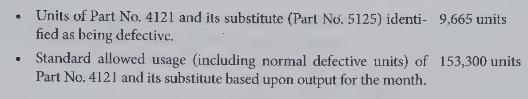

The materials variances for several of the parts Maidwell uses are unfavorable. Part No. 4121 is one of the items that has an unfavorable variance. Maidwell knows that some of these parts will be defective and fail. The failure is discovered during production. The normal defective rate is \(5 \%\) of normal input. The original contract price of this part was \(\$ .285\) per unit; thus, Maidwell set the standard unit price at \(\$ .285\). The unit contract purchase price of Part No. 4121 was increased \(\$ .04\) to \(\$ .325\) from the original \(\$ .285\) due to a parts specification change. Maidwell chose not to change the standard, but treat the increase in price as a price variance. In addition, the contract terms were changed from \(n / 30\) to \(4 / 10, n / 30\) as a consequence of negotiations resulting from changes in the economy.

Bob Speck, the purchasing director, claims the unfavorable price variance is misleading. Speck says that his department has worked hard to obtain price concessions and purchase discounts from suppliers. In addition, Speck has indicated that engineering changes have been made in several parts increasing their price even though the part identification has not changed. These price increases are not his department's responsibility. Speck declares that the price variance simply no longer measures the purchasing department's performance.

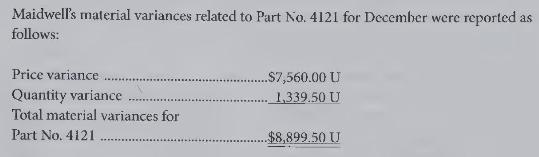

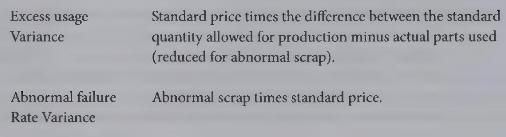

Jim Buddle, the manufacturing manager, thinks that responsibility for the quantity variance should be shared. Buddle states that manufacturing cannot control quality arising from less expensive parts, substitutions of material to use up otherwise obsolete stock, or engineering changes that increased the quantity of materials used. The accounting manager, Mike Kohl, has suggested that the computation of variances be changed to identify variations from standard with the causes and functional areas responsible for the variances. The following system of materials variances and the method of computation for each was recommended by Kohl.

{Required:}

(a) Discuss the appropriateness of Maidwell Company's current method of variance analysis for materials and indicate whether the claims of Bob Speck and Jim Buddle are valid.

(b) Compute the materials variances for Part No. 4121 for December using the system recommended by Mike Kohl.

(c) Indicate who would be responsible for each of the variances in Mike Kohl's system of variance analysis for materials.

Step by Step Answer:

Cost Accounting For Managerial Planning Decision Making And Control

ISBN: 9781516551705

6th Edition

Authors: Woody Liao, Andrew Schiff, Stacy Kline