Question: A pharmaceutical product P. is made in a batch reactor. The reactor effluent goes through a purification process to yield a final product stream and

A pharmaceutical product P. is made in a batch reactor. The reactor effluent goes through a purification process to yield a final product stream and a waste stream. The initial charge (feed) to the reactor and the final product are each weighed, and the reactor effluent, final product and waste stream are each analyzed for P. The analyzer calibration is a series of meter readings. K. corresponding to known mass fractions of P. xp.

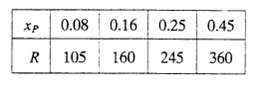

(a) Plot the analyzer calibration data on logarithmic axes and determine an expression for xp (R).

(b) The data sheet for one run is shown below:

Batch #: 23601 Date: 10/4

Mass charged to reactor: 2253 kg

Mass of purified product: 1239 kg

Reactor effluent analysis: R = 388

Final product analysis: R = 583

Waste stream analysis: R = 140

Calculate the mass fractions of P in all three streams. Then calculate the percentage yield of the purification process. YP = kg P in final product/kg P in reactor effluent x 100%

(c) You are the engineer in charge of the process. You review the given run sheet and the calculations of part (b), perform additional balance calculations, and realize that all of the recorded run data cannot possibly be correct. State how you know, itemize possible causes of the problem state which cause is most likely, and suggest a step to correct it.

Xp 0.08 0.16 0.25 R 105 160 245 0.45 360

Step by Step Solution

3.28 Rating (174 Votes )

There are 3 Steps involved in it

a Feed 2253 kg te 1 01 001 100 Reactor Reactor effluent 2253kg R 388 Ana... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (2 attachments)

13-E-C-E-C-P (112).pdf

180 KBs PDF File

13-E-C-E-C-P (112).docx

120 KBs Word File