A solvent-recovery plant consists of a plate-column absorber and a plate-column stripper. Ninety percent of the benzene

Question:

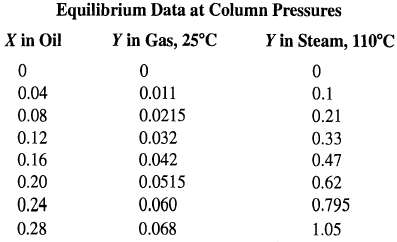

A solvent-recovery plant consists of a plate-column absorber and a plate-column stripper. Ninety percent of the benzene (B) in the gas stream is recovered in the absorption column. Concentration of benzene in the inlet gas is 0.06 mol B/mol B-free gas. The oil entering the top of the absorber contains 0.01 mol B/mol pure oil. In the leaving liquid, X = 0.19 mol Blmol pure oil. Operating temperature is 77°F (25°C). Open, superheated steam is used to strip benzene out of the benzene-rich oil at 110°C. Concentration of benzene in the oil = 0.19 and 0.01 (mole ratios) at inlet and outlet, respectively. Oil (pure)-to-steam (benzene-free) flow rate ratio = 2.0. Vapors are condensed, separated, and removed.

(a) The molar flow rate ratio of B-free oil to B-free gas in the absorber;

(b) The number of theoretical plates in the absorber; and

(c) The minimum steam flow rate required to remove the benzene from 1 mol of oil under given terminal conditions, assuming an infinite-platescolumn.

Step by Step Answer: