Question:

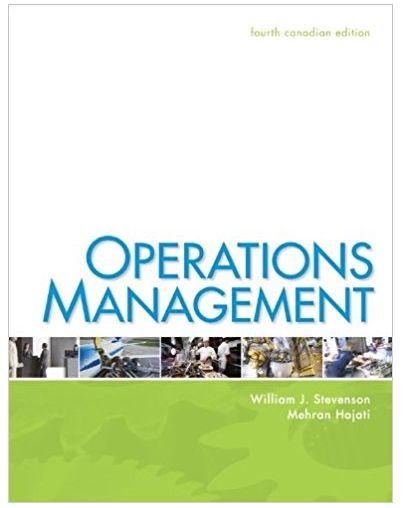

Consider the chair described in Figure 14-5. Suppose that the chair is made by a small furniture manufacturer that has just received an order to deliver 100 chairs on Monday April 20. The production/purchase planner needs to arrange for the purchase of parts and their assembly. The chairs, front assemblies, and back assemblies are to be assembled by one worker each. During an 8-hour day, 100 front assemblies and 50 back assemblies can be assembled. After a batch of 100 front assemblies and 100 back assemblies are produced, the whole chair will be assembled at the rate of 50 per 8-hour day. The company works 5 days a week. The seats, front legs, cross bars, side rails, and back supports are purchased from another company. The purchase lead time for any order is one work day. The company has some inventory of parts from previous purchases: 100 front legs, 160 cross bars, 40 side rails, and 90 back supports. All items are purchased or assembled lot-for-lot, except cross bars, which are purchased in a lot size of 200. In anticipation for this order, an order of 100 seats has already been placed and is expected on Monday April 13.

a. Calculate the assembly lead times for the chairs, front assemblies, and back assemblies required for this order.

b. Develop tire material requirements plans for this order. What action should you take now?

Figure 14-5

Transcribed Image Text:

Assembly diagram Finished chair Back support Indented BOM Chair Crossbar Front leg Back Assembly Side rail (2) Cross-bar Cross- bar Seat Back support (3) Cross bar Front Assambly Side rail Front leg (2) Product structure tree Cross-bor Chair Cross-bar (2) Front Back assembly Seat Cross-bar (2) assembly Front Cross Leg 12) bar SideCross Back rail (2) bar support (3)

.png)