Determine the appropriate size of a shell-and-tube heat exchanger with two tube passes and one shell pass

Question:

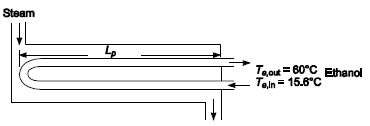

Determine the appropriate size of a shell-and-tube heat exchanger with two tube passes and one shell pass to heat 70,000 lb/h (8.82 kg/s) of pure ethanol from 60 to 140?F (15.6 to 60?C). The heating medium is saturated steam at 22 psia (152 kPa) condensing on the outside of the tubes with a condensing coefficient of 15,000 W/(m2K). Each pass of the exchanger has 50 copper tubes with an OD of 0.75 in (1.91 cm) and a wall thickness of 0.083 in (0.211 cm). For the sizing, assume the header cross-sectional area per pass is twice the total inside tube cross-sectional area. The ethanol is expected to foul the inside of the tubes with a fouling coefficient of 1000 Btu/(h ft2 ?F) (5678W/(m2 K)) . After the size of the heat exchanger, i.e., the length of the tubes, is known, estimate the frictional pressure drop using the inlet loss coefficient of unity. Then estimate the pumping power required with a pump efficiency of 60% and the pumping cost per year with $0.10 per kw-hr.GIVENShell-and-tube heat exchanger, ethanol in copper tubes, steam in shellOne shell pass and two tube passesEthanol flow rate me = 8.82 kg/sEthanol temperaturesTe,in = 15.6?CTe,out = 60?CSteam pressure = 152 kPaNumber of tubes (N) = 50Tube outside diameter (Do) = 1.91 cm = 0.0191 mTube wall thickness (t) = 0.211 cm = 0.00211 mHeader area per pass = 2 (total inside cross-sectional area)Tube side fouling coefficient (1/Ri) = 5678 W/(m2 K)Shell-side transfer coefficient (ho) = 15,000 W/(m2 K)ASSUMPTIONSThe variation of thermal properties with temperature is negligibleShell side fouling is negligibleThe tubes are smoothEntrance pressure drop effects arenegligible

Step by Step Answer:

Principles of heat transfer

ISBN: 978-0495667704

7th Edition

Authors: Frank Kreith, Raj M. Manglik, Mark S. Bohn