Question: In the final stage of the manufacturing process for a solid organic product, the product is cleaned with liquid toluene and then dried in a

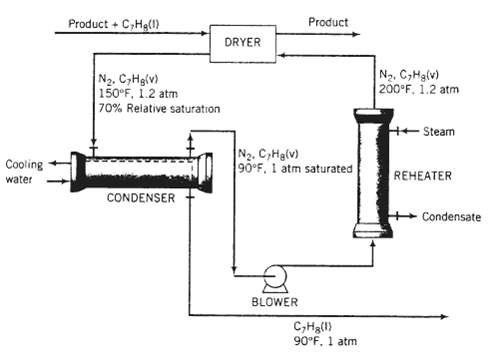

In the final stage of the manufacturing process for a solid organic product, the product is cleaned with liquid toluene and then dried in a process whose flowchart is shown on the next page10. The wet product enters the dryer at a rate of 300lbm/h containing 0.200lbm toluene/lbm dry solids. A stream of nitrogen at 200?F, 1.2 atm. and containing a small amount of toluene vapor also enters the dryer. (A higher temperature would cause the product to soften and degrade.) Heat is transferred in the dryer from the gas to the wet solids, causing most of the toluene to evaporate. The final product contains 0.020lbm toluene/lbm dry solids. Gas leaves the dryer at 150?F and 1.2 atm with a relative saturation of 70% and passes through a water-cooled condenser. Gas and liquid streams leave the condenser in equilibrium at 90?F and 1 atm. The gas is reheated to 200?F and reenters the dryer.

(a) Calculate the compositions (component mole fractions) of the gas streams entering and leaving the dryer, the circulation rate of dry nitrogen (lbm/h), and the volumetric flow rate of gas entering the dryer (ft3/h).

Cooling water Product + CyH(1) N. CHg(v) 150F, 1.2 atm 70% Relative saturation CONDENSER DRYER Product N. CyHg(v) 90F, 1 atm saturated BLOWER CH(1) 90F, 1 atm N, CHg(v) 200F. 1.2 atm +++ Stearn REHEATER Condensate

Step by Step Solution

3.52 Rating (162 Votes )

There are 3 Steps involved in it

a 300 lbh wet product 02 1 02 0833 lbm D1bm 0167 lbm T1 lbm lbmoleh y lbmole Tv1bmole 1yi lbmol... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (2 attachments)

13-E-C-E-C-P (288).pdf

180 KBs PDF File

13-E-C-E-C-P (288).docx

120 KBs Word File