Question: A mixture (A) in a continuous pharmaceutical manufacturing process Contains up to 10 wt% of an ingredient R [mass fraction x RA (g R/g A)1.

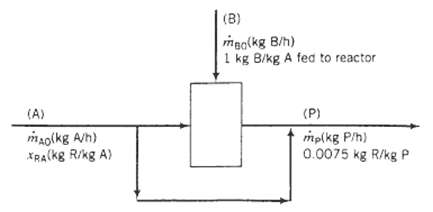

A mixture (A) in a continuous pharmaceutical manufacturing process Contains up to 10 wt% of an ingredient R [mass fraction xRA (g R/g A)1. The mixture is subjected to a reaction step in which the conversion of R is 99%. The final product (P) must contain 0.75 wt% R. To achieve this goal, a fraction f of the A fed to the process bypasses the reactor and combines with the product stream leaving the reactor to produce P. A second feed stream (B), which contains no R, enters the reactor along with the A not bypassed. The mass flow rates of A and B entering the reactor (not the process) are equal.

(a) Without taking a basis of calculation, draw and label a flowchart. Then list the equations you are allowed to write for the stream splitting and mixing points and the reactor, and prove that the process has two degrees of freedom. (Be careful when counting allowable balances on the pre-reactor stream splitting point.)

(b) Suppose the production rate of the final product. mp, and the mass fraction of R in the process feed. xRA, are known. Write a set of equations that may be solved for the rates, mA0 (kg/h) and mB0 (kg/h), at which A and B must be fed to the process (not the reactor), and for the fraction of the process feed, f (kg bypass/kg fresh feed), that must be bypassed to achieve the desired mass fraction of R in the final product (0.0075 kg R/kg P). Do not perform any numerical calculations.

(c) Suppose mp = 4850 kg P/h and xRA = 0.0500 kg R/kg A. Calculate mA0, mB0, and f.

(A) mao(kg A/h) XRA(Kg R/kg A) (B) mao(kg B/h) 1 kg B/kg A fed to reactor (P) mp(kg P/h) 0.0075 kg R/kg P

Step by Step Solution

3.40 Rating (163 Votes )

There are 3 Steps involved in it

a b A mo kgh XRA kg Rkg 1fm kgh XR4 kg Rkg 21fm m MXR1 0011fmOXRA m fm mp B 1fm kgh XR0 mXR1fmXR 000... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (2 attachments)

13-E-C-E-C-P (154).pdf

180 KBs PDF File

13-E-C-E-C-P (154).docx

120 KBs Word File