OBrien Corporation is a midsize, privately owned, industrial instrument man ufacturer supplying precision equipment to manufacturers in

Question:

O’Brien Corporation is a midsize, privately owned, industrial instrument man¬ ufacturer supplying precision equipment to manufacturers in the Midwest. The corpo¬ ration is 10 years old and operates a centralized AIS. The administrative offices are located in a downtown building and the production, shipping, and receiving depart¬ ments are housed in a renovated warehouse a few blocks away. The shipping and receiving areas share one end of the warehouse.

The marketing department consists of four sales representatives. Upon obtaining an order over the telephone, a salesperson manually prepares a prenumbered, two- part sales order. One copy of the order is filed by date and the second copy is sent to the shipping department. All sales are on credit, FOB destination. Because of the recent increase in sales, the sales representatives have not had time to check credit histories. As a result, 15% of credit sales are either late collections or uncollectible.

The shipping department receives the sales orders and packages the goods from the warehouse, noting any items that are out of stock. The terminal in the shipping department is used to update the perpetual inventory records of each item as it is removed from the shelf. The packages are placed near the loading dock door in alpha¬ betical order by customer name. A shipping clerk signs the sales order, indicating that the order is filled and ready to send.

The sales order is forwarded to the billing department, where a two-part sales invoice is prepared. The sales invoice is prepared upon receipt of the sales order from the shipping department so that the customer is billed only for the items that were sent, not for back orders. Billing sends the customer’s copy of the invoice back to shipping, and shipping then inserts it into a special envelope on the package in order to save postage.

The carrier of the customer’s choice is then contacted to pick up the goods. In the past, goods were shipped within two working days of receipt of the customer’s order; however, shipping dates now average six working days. One reason for this slippage is that two new shipping clerks are still undergoing training. Because these clerks have fallen behind, the two experienced clerks in the receiving department have been assisting them.

The receiving department is located adjacent to the shipping dock, and many different carriers deliver merchandise daily. The receiving clerks share a computer terminal with the shipping department. The date, vendor, and number of items received are entered upon receipt to keep the perpetual inventory records current.

Hard copies of the changes in inventory (additions and shipments) are printed monthly. The receiving supervisor checks that the additions are reasonable and for¬ wards the printout to the shipping supervisor, who is responsible for checking the reasonableness of the deductions from inventory (shipments). The inventory printout is stored in the shipping department by date. A complete inventory list is printed only once a year when the entire inventory is counted.

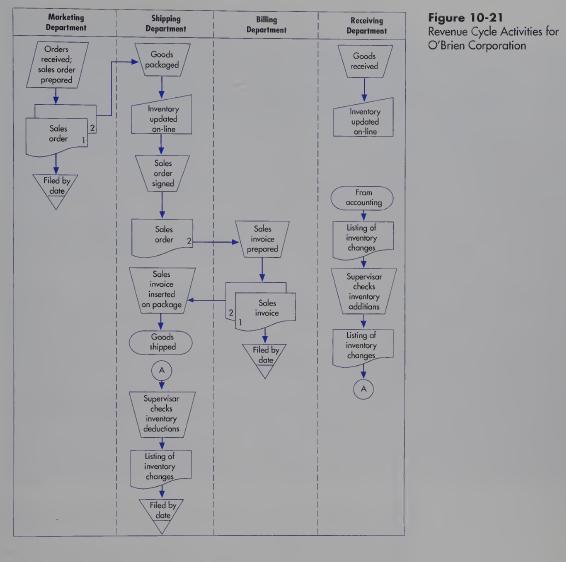

Figure 10-21 presents the document flows employed by O’Brien Corporation.

Required

a. Identify at least five weaknesses in O’Brien Corporation’s marketing, ship¬ ping, billing, and receiving information system. Describe the exposure resulting from each weakness. Recommend control procedures that should be added to the system to correct the weakness. Format your answer as follows:

Weakness Threat Recommended Control Procedure(s)

b. Discuss how O’Brien Corporation could use IT to improve both control and efficiency during sales order processing.

Step by Step Answer: