Production problems. A manufacturing company that makes dental drills was experiencing problems with a specific part on

Question:

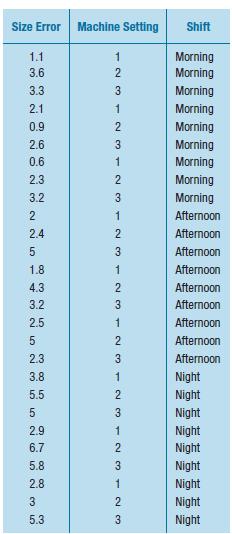

Production problems. A manufacturing company that makes dental drills was experiencing problems with a specific part on the production line. Management suspected a machining problem that resulted in the length of the part to vary outside of target specification. Two factors were examined:

the machine setting (at three levels) and the shift

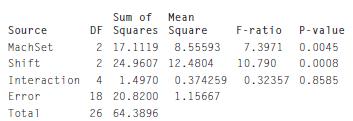

(morning, afternoon, and night). New hires were typically scheduled for night shift, and management believed that their relative inexperience may also be contributing to the variation. Three parts were randomly selected and measured from each treatment combination. The deviation from specified size was measured in microns. The data and two-way ANOVA results are shown.

a) Is this an experiment or an observational study? Explain.

b) What is the response variable?

c) How many treatments are involved?

d) Based on the two-way ANOVA results, management concluded that shift has a significant impact on the length of the part and that consequently operator inexperience is the root cause of the part problems. Do you agree with this conclusion? Explain.

Step by Step Answer:

Business Statistics

ISBN: 9780321716095

2nd Edition

Authors: Norean D. Sharpe, Paul F. Velleman, David Bock, Norean Radke Sharpe