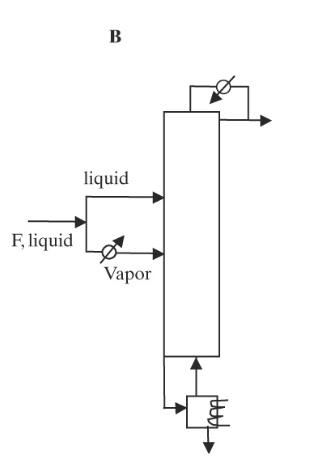

a. Repeat Problem 10.G3 except use the method shown in Figure 1018B to partially balance the column

Question:

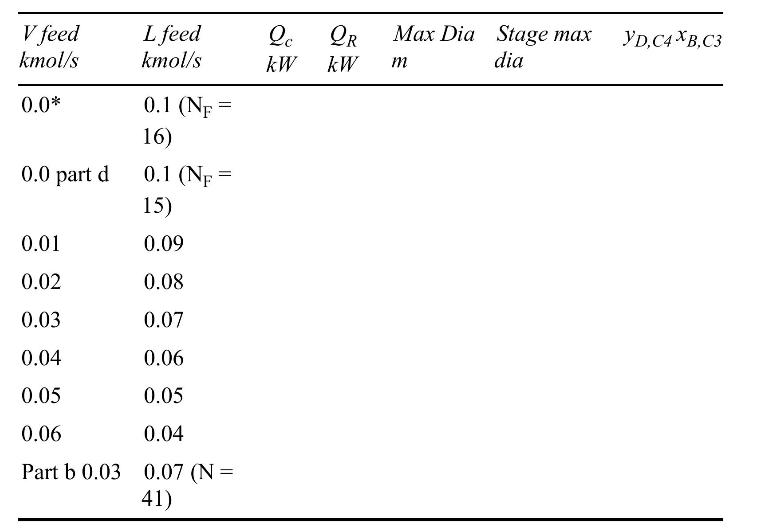

a. Repeat Problem 10.G3 except use the method shown in Figure 1018B to partially balance the column diameters. The liquid and vapor feeds have the same mole fractions as the feed in Problem 10.G3, and both are at \(15.0 \mathrm{~atm}\). The liquid feed is at \(25.0^{\circ} \mathrm{C}\), and the vapor feed is a saturated vapor. Input the liquid feed on stage 15 . Input the vapor feed as a vapor on stage 18. Treat the column as a single section with one pass. Vary the vapor feed and the liquid feed and record the values in the following table.

\(\mathrm{Q}_{\mathrm{R}}\) decreases, but since energy will be required to vaporize the feed, the net change in heating requirement is negligible. The maximum diameter decreases, but the purity of the distillate and the bottoms decreases.

b. To obtain a purer product, increase \(\mathrm{N}\) (Aspen notation) to 41, use \(\mathrm{N}_{\mathrm{F}, \mathrm{liq}}=18\) and \(\mathrm{N}_{\mathrm{F}, \text { vap }}=21\). Then repeat the run with \(0.03 \mathrm{kmol} / \mathrm{s}\) of vapor feed and \(0.07 \mathrm{kmol} / \mathrm{s}\) of liquid feed. Compare with the allliquid feed run. How much volume decrease is there in the column?

c. Do a tray-rating run with the diameter calculated in part \(\mathrm{b}\), and use defaults for tray spacing and for the downcomer. Record the maximum downcomer backup and the tray at which it occurs and the maximum weir loading and the tray at which it occurs.

d. Since Problem 10.G3 has not been optimized, try feed of the liquid on stage 15 with no vapor feed. Record the maximum downcomer backup and the tray at which it occurs and the maximum weir loading and the tray at which it occurs.

Data From 10.G3

We wish to distill \(0.10 \mathrm{kmol} / \mathrm{s}\) of a feed at \(25^{\circ} \mathrm{C}\) and \(15.0 \mathrm{~atm}\). The feed is \(10.0 \mathrm{~mol} \%\) ethane, \(35.0 \mathrm{~mol} \%\) propane, \(45.0 \mathrm{~mol} \% \mathrm{n}\)-butane, and \(10.0 \mathrm{~mol} \% \mathrm{n}-\mathrm{pentane.} \mathrm{Use} \mathrm{the} \mathrm{Peng-Robinson} \mathrm{VLE} \mathrm{correlation.} \mathrm{Design}\) a column with \(\mathrm{N}\) (Aspen notation) \(=35\) and the feed on stage 16 . The column operates at \(15.0 \mathrm{~atm}\), has a partial condenser, and produces a vapor distillate with \(\mathrm{D}=0.0450 \mathrm{kmol} / \mathrm{s}\). A kettle-type reboiler is used. Reflux ratio is \(\mathrm{L} / \mathrm{D}=2.4\).

a. Do tray sizing using the Fair flooding method with \(70 \%\) flooding, \(0.6 \mathrm{~m}\) distance between plates, and default values for the other tray parameters. Find the largest column diameter and the mole fractions of distillate (vapor) and bottoms.

b. Do tray rating for this single-section column with one pass, with weir height of \(0.0508 \mathrm{~m}\), the same diameter calculated in part

a, and default values for the other parameters. Leave the Downcomers tab blank. Report the worst downcomer backup (amount and stage) and the weir loading \(\mathrm{m}^{2} / \mathrm{s}\).

c. Design a two-pass system and compare it to the one-pass system.

Figure 10-18

Step by Step Answer:

Separation Process Engineering Includes Mass Transfer Analysis

ISBN: 9780137468041

5th Edition

Authors: Phillip Wankat