Question: Redo Example 20-3 but with co-current thermal regeneration. Input the hot thermal wave (co-current purge step at superficial velocity of (11.0 mathrm{~cm} / mathrm{min}) )

Redo Example 20-3 but with co-current thermal regeneration. Input the hot thermal wave (co-current purge step at superficial velocity of \(11.0 \mathrm{~cm} / \mathrm{min}\) ) so that it exits at same time xylene breaks through at the product end. Stop the hot thermal wave as soon as thermal breakthrough occurs, and input cold feed (at superficial velocity of \(8.0 \mathrm{~cm} / \mathrm{min}\) ). Find feed time, time last solute leaves the column, average mass fraction of peak from initial breakthrough to last solute leaving, and time that gas exiting the column becomes cold again. Compare average outlet mass fraction of peak to average mass fraction of gas exiting during regeneration in Example 20-3.

Data From Example 20-3

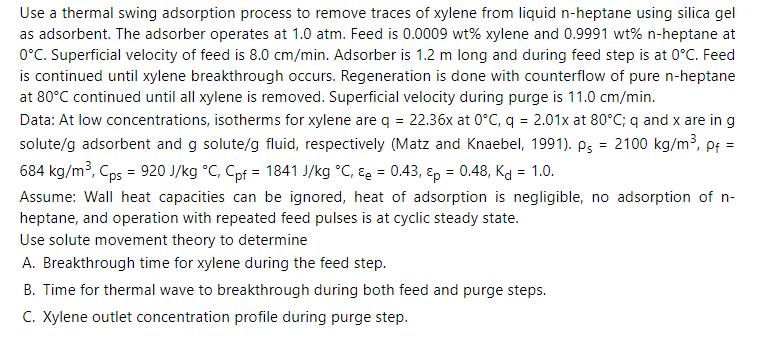

Use a thermal swing adsorption process to remove traces of xylene from liquid n-heptane using silica gel as adsorbent. The adsorber operates at 1.0 atm. Feed is 0.0009 wt% xylene and 0.9991 wt% n-heptane at 0C. Superficial velocity of feed is 8.0 cm/min. Adsorber is 1.2 m long and during feed step is at 0C. Feed is continued until xylene breakthrough occurs. Regeneration is done with counterflow of pure n-heptane at 80C continued until all xylene is removed. Superficial velocity during purge is 11.0 cm/min. Data: At low concentrations, isotherms for xylene are q = 22.36x at 0C, q = 2.01x at 80C; q and x are in g solute/g adsorbent and g solute/g fluid, respectively (Matz and Knaebel, 1991). Ps = 2100 kg/m, pf = 684 kg/m, Cps = 920 J/kg C, Cpf = 1841 J/kg C, & = 0.43, p = 0.48, Kd = 1.0. Assume: Wall heat capacities can be ignored, heat of adsorption is negligible, no adsorption of n- heptane, and operation with repeated feed pulses is at cyclic steady state. Use solute movement theory to determine A. Breakthrough time for xylene during the feed step. B. Time for thermal wave to breakthrough during both feed and purge steps. C. Xylene outlet concentration profile during purge step.

Step by Step Solution

3.40 Rating (147 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts