Question: (a) Consider the flash separation process shown in Figure 7.1. If using ASPEN PLUS, solve all three cases using the MIXER, FLASH2, FSPLIT, and PUMP

(a) Consider the flash separation process shown in Figure 7.1. If using ASPEN PLUS, solve all three cases using the MIXER, FLASH2, FSPLIT, and PUMP modules and the RK-SOAVE option set for themophysical properties. Compare and discuss the flow rates and compositions for the overhead stream produced by each of the three cases.

(b) Modify case 3 of Exercise 7.1a to determine the flash temperature necessary to obtain \(850 \mathrm{lb} / \mathrm{hr}\) if overhead vapor. If using ASPEN PLUS, a design specification can be used to adjust the temperature of the flash drum to obtain the desired overhead flow rate.

Data From Figure 7.1:-

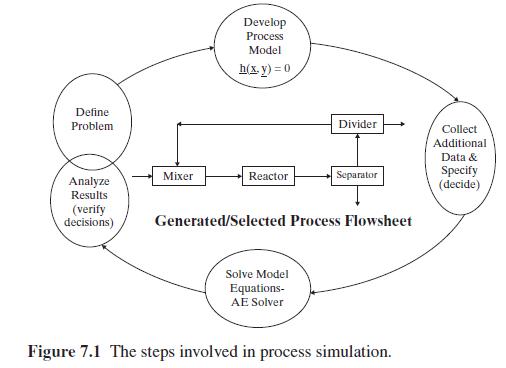

Define Problem Mixer Analyze Results (verify decisions) Develop Process Model h(x,y)=0 Reactor Divider Collect Additional Data & Separator Specify (decide) Generated/Selected Process Flowsheet Solve Model Equations- AE Solver Figure 7.1 The steps involved in process simulation.

Step by Step Solution

3.47 Rating (150 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts