Question: A common application of control systems is in regulating the temperature of a chemical process (Figure P6.13). The flow of a chemical reactant to a

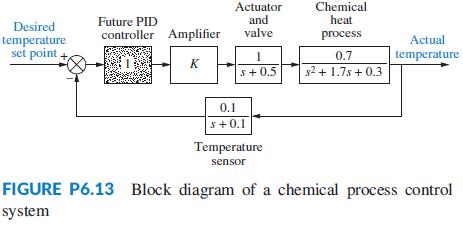

A common application of control systems is in regulating the temperature of a chemical process (Figure P6.13). The flow of a chemical reactant to a process is controlled by an actuator and valve. The reactant causes the temperature in the vat to change. This temperature is sensed and compared to a desired set-point temperature in a closed loop, where the flow of reactant is adjusted to yield the desired temperature. We will learn how a PID controller is used to improve the performance of such process control systems. Figure P6.13 shows the control system prior to the addition of the PID controller. The PID controller is replaced by the shaded box with a gain of unity. For this system, prior to the design of the PID controller, find the range of amplifier gain, K, to keep the system stable.

Actuator and Chemical heat Future PID Desired controller Amplifier valve process temperature Actual set point . temperature 0.7 K s+ 0.5 g2 + 1.7s + 0.3 0.1 s+0.1 Temperature sensor FIGURE P6.13 Block diagram of a chemical process control system

Step by Step Solution

3.22 Rating (157 Votes )

There are 3 Steps involved in it

Calculating Transfer Function InputDesire Temperature Set Point S t Output Actual Tempe... View full answer

Get step-by-step solutions from verified subject matter experts