Obtaining an exact shape in metal forming can be tricky because of material spring back. A feedback

Question:

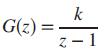

Obtaining an exact shape in metal forming can be tricky because of material spring back. A feedback system has been devised in which critical deviations from specifications are measured as soon as a part is formed and automatic incremental corrections to the forming tools are made before the next part is formed. Eventually the system compensates for material spring back and results in parts compliant with specifications. A unity-feedback digital system with a forward path

can be used as a simplified representation of the system (Fu, 2013).

a. Make a sketch of the system’s root locus.

b. Find the range of k for which the system is closed loop stable.

c. Find the system’s steady-state error for a step input.

d. Find the value of k that will result in the fastest possible response.

Step by Step Answer: