As part of its cost control program. Tracer Company uses a standard cost system for all man

Question:

As part of its cost control program. Tracer Company uses a standard cost system for all man¬

ufactured items. The standard cost for each item is established at the beginning of the fis¬

cal year, and the standards are not revised until the beginning of the next fiscal year. Changes in costs, caused during the year by changes in material or labor inputs or by changes in the manufacturing process, are recognized as they occur by the inclusion of planned variances in Tracer's monthly operating budgets.

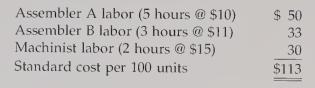

Presented below is the labor standard that was established for one of Tracer's products effective June 1, 2001, the beginning of the fiscal year:

The standard was based on the labor being performed by a team consisting of 5 per¬

sons with Assembler A skills, 3 persons with Assembler B skills, and 2 persons with ma¬

chinist skills; this team represents the most efficient use of the company's skilled employ¬

ees. The standard also assumed that the quality of materials that had been used in prior years would be available for the coming year.

For the first seven months of the fiscal year, actual manufacturing costs at Tracer have been within the standards established. However, the company has received a significant increase in orders, and there is an insufficient number of skilled workers to meet the in¬

creased production. Therefore, beginning in January, the production teams will consist of 8 persons with Assembler A skills, 1 person with Assembler B skills, and 1 person with machinist skills. The reorganized teams will work more slowly than the normal teams, and as a result, only 80 units will be produced in the same time period in which 100 units would normally be produced. Faulty work has never been a cause for units to be rejected in the final inspection process, and it is not expected to be a cause for rejection with the reorga¬

nized teams.

Furthermore, Tracer has been notified by its materials supplier that lower-quality ma¬

terials will be supplied beginning January 1. Normally, one unit of raw materials is required for each good unit produced, and no units are lost due to defectiv'e material. Tracer esti¬

mates that 6/o of the units manufactured after January 1 will be rejected in the final in¬

spection process due to defective material.

Required:

1. Determine the number of units of lower-quality material that Tracer Company must en¬

ter into production in order to produce 47,000 good finished units.

2. How many hours of each class of labor must be u.sed to manufacture 47,000 good fin¬

ished units?

3. Determine the amount that should be included in Tracer's [anuary operating budget for the planned labor variance cau.sed by the reorganization of the labor teams and the lower-quality material.

Step by Step Answer:

Cost Management Accounting And Control

ISBN: 9780324002324

3rd Edition

Authors: Don R. Hansen, Maryanne M. Mowen