In 20x1, Fleming Chemicals used the following input combination to produce 55,000 gallons of an industrial solvent:

Question:

Materials€¦€¦€¦€¦€¦€¦€¦€¦€¦.33,000 lbs.

Labor€¦€¦€¦€¦€¦€¦€¦€¦€¦€¦€¦..66,000 hrs.

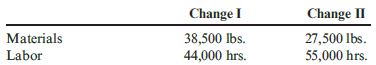

In 20x2, Fleming again planned to produce 55,000 gallons of solvent and was considering two different changes in process, both of which would be able to produce the desired output. The following input combinations are associated with each process change:

The following combination is optimal for an output of 55,000 units. However, this optimal input combination is unknown to Fleming.

Materials€¦€¦€¦€¦€¦.22,000 lbs.

Labor€¦€¦€¦€¦€¦€¦€¦..44,000 hrs.

The cost of materials is $60 per pound, and the cost of labor is $15 per hour. These input prices hold for 20x1 and 20x2.

Required:

1. Compute the productivity profiles for each of the following:

a. The actual inputs used in 20x1

b. The inputs for each proposed 20x2 process change

c. The optimal input combination. Will productivity increase in 20x2, regardless of which change is used? Which process change would you recommend based on the prospective productivity profiles?

2. Compute the cost of 20x1€™s productive inefficiency relative to the optimal input combination. Repeat for 20x2 proposed input changes. Will productivity improve from 20x1 to 20x2 for each process change? If so, by how much? Explain. Include in your explanation a discussion of changes in technical and allocative efficiency.

3. Since the optimal input combination is not known by Fleming, suggest a way to measure productivity improvement. Use this method to measure the productivity improvement achieved from 20x1 to 20x2. How does this measure compare with the productivity improvement measure computed using the optimal input combination?

Step by Step Answer:

Cornerstones of Cost Management

ISBN: 978-1305970663

4th edition

Authors: Don R. Hansen, Maryanne M. Mowen