Homaid Pickles was started by Mary Hyde some years ago and has developed rapidly. The emphasis is

Question:

Homaid Pickles was started by Mary Hyde some years ago and has developed rapidly.

The emphasis is on fresh, high quality ingredients and unusual flavours. The main outlets are high class departmental stores, mail order and delicatessens and trade is booming. In the early days, Mary was able to oversee every stage in the manufacturing process and was thus able to control costs in a direct and personal way. Those times have long since gone and over the last few years she has concentrated on marketing the products. As a consequence control over manufacturing has slipped and Mary feels sure that yields and costs could be improved if only she could obtain up-to-date and relevant control information.

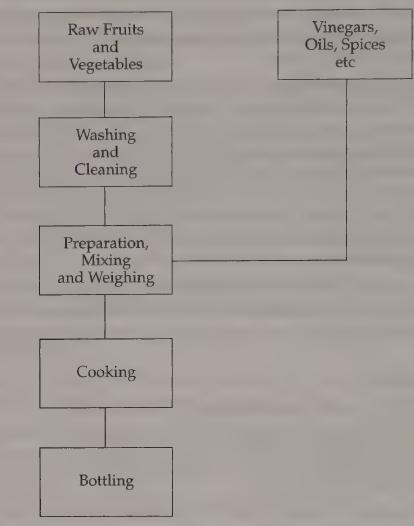

All products follow the same processes which can be shown as follows:

The key process is that of Preparation, Mixing and Weighing because at that stage, costs, yields and quality are determined.

She discusses the problem with Bob Allen, her newly appointed Factory Manager. He thinks that some form of Standard Process costing would provide useful information but Mary is far from convinced. She suggests that Bob prepares some information for her based on last week’s production of one of their best selling lines, 3L Pickle; which is made from Lemons, Leeks and Loganberries.

With the assistance of a friend, who is an accountant, Bob sets to work. A summary of what he found follows:

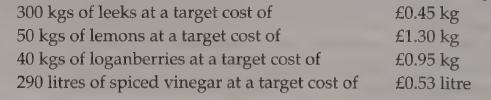

The recipe card for the 3L Pickle showed that it is made in batches. Each batch is expected to produce 2000, 250 gram jars of pickle from the following ingredients:

(the vinegar price is the equivalent of £0.59 kg)

Typically a batch is expected to take the Pickle Team seven hours. The team comprises a Chargehand paid £4.25 per hour and four Operatives paid £3.10 per hour.

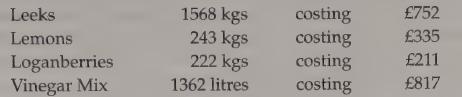

Bob found that five batches of 3L Pickle were made in the week and after analysing the wages paid and invoices he found that the actual costs were:

39 hours were worked by the Pickle Team at a total cost of £682. The output of pickles for the week was 9340 jars.

Bob was fairly sure he now had sufficient data to produce an example of the type of control information that could be made available.

Questions:-

1. Does this seem to be a reasonable application of standard process costing?

2. What are the likely benefits if a system is introduced?

3. Outline how a system could be installed in Homaid Pickles.

4. What is a reasonable estimate of the standard prime cost of a batch of 3L Pickle?

5. What is the percentage expected loss?

6. What is the standard prime cost of a 250 gram jar of pickle?

7. Calculate the following variances for the week:

8. What was the actual percentage loss in yield?

9. Interpret the meaning of these variance and explain how control would be assisted by their preparation.

10. Do you think that there are any alternative methods of maintaining control over costs and yields? If so, what?

Step by Step Answer: