Changing standards for alternative production methods Opake Products Corporation fab- ricates a variety of products from sheet

Question:

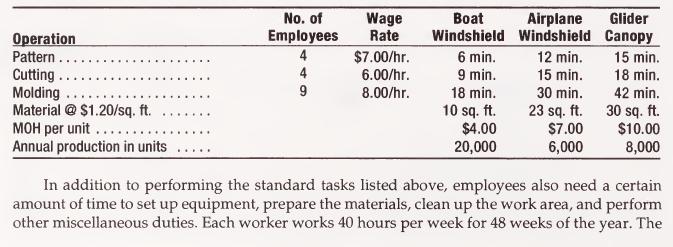

Changing standards for alternative production methods Opake Products Corporation fab- ricates a variety of products from sheet plastics. One division uses clear plastics to mold windshields and canopies for boats, airplanes, and gliders. The process involves marking appro- priate patterns on the sheet plastic, cutting them into individual pieces, and heating the material until it is flexible enough to be draped in either a positive or negative mold to form the appropriate shape. The process is performed primarily by the manual labor of the department's 17 employees. The company uses a job order cost system with the following standard costs:

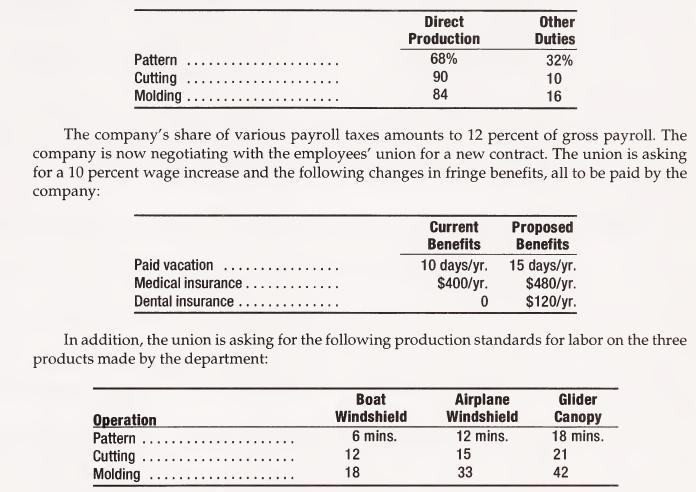

remaining four weeks consist of unpaid holidays and paid vacation. Of the total time worked, employees spend the following approximate proportions on direct production and other duties:

Company negotiators point out that the above standards represent almost 5 percent addi- tional labor time for production. This would require either producing fewer products or hiring more workers. The union claims, however, that only one more worker would have to be hired to perform some of the setup and other production tasks that the production workers now do. The new employee would earn only $5.50 per hour because the job does not involve any of the fabricating operations. However, the new employee would be entitled to all the benefits provided to the other workers. If the new standards, wage rates, and additional employee are used by the company, manufacturing overhead on the three products is expected to be: Boat windshield, $4.20; airplane windshield, $7.35; and glider canopy, $10.50. These figures do not include the gross pay of the new employee, which would be considered direct labor.

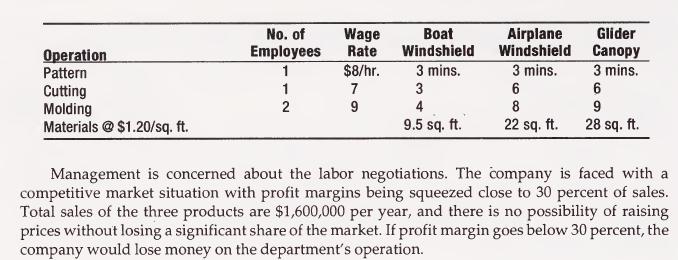

During the labor negotiations, the company was approached by a representative of a robot manufacturer. The representative's company proposes to supply automatic digital-controlled equipment that would perform most of the labor operations in the department more precisely and faster than the current manual process. The new equipment would design cutting patterns with a minimum of waste material, cut them automatically, and heat them uniformly for automatic molding using the company's present molds.

The automatic equipment would increase manufacturing overhead on each unit of product by 50 percent above the current overhead rate. It would require a labor force of only 4 employees to operate the equipment. These more highly trained employees would have a higher salary, but would have the same fringe benefits now requested by the union. If the company were to acquire the new equipment, the following standards could be established for the products:

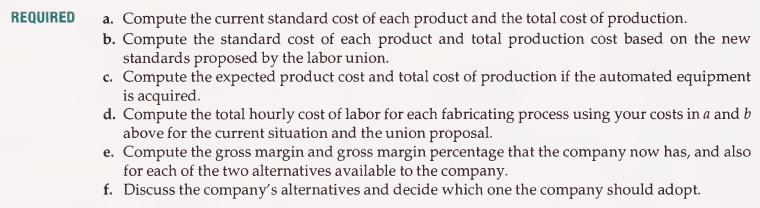

Step by Step Answer: