Determine Optimal Safety-Stock Levels: The Starr Company manufactures several products. One of its main products re- quires

Question:

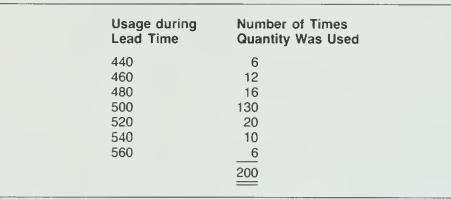

Determine Optimal Safety-Stock Levels: The Starr Company manufactures several products. One of its main products re- quires an electric motor. The management of Starr Company uses the EOQ model to determine the optimum number of motors to order. Management now wants to determine how much safety stock to keep on hand. The company uses 30,000 motors annually at the rate of 100 per working day. The motors regularly cost $60 each. The lead time for an order is five days. The cost to carry a motor in stock is $10. The cost to place an order is $1500. If a stockout occurs, management must purchase motors at retail from an alternate supplier. The alternate supplier charges $80 per motor. Starr Company has analyzed the usage during the past reorder periods by examining inventory records. The records indicate the following usage patterns during past reorder periods:

Required: Determine the least-cost safety-stock level and the total differential costs at that level, ignoring the cost of capital. (The optimal order size must also be derived.)

Step by Step Answer: