Determine Optimal Safety-Stock Levels: Wildridge Products, Inc., has expressed concern over the erratic delivery times for a

Question:

Determine Optimal Safety-Stock Levels: Wildridge Products, Inc., has expressed concern over the erratic delivery times for a critical product, Westovers. The company orders 3,000 at a time and has maintained a safety stock of 200 Westovers but has been experiencing frequent stockouts and production delays. The plant operates 270 days per year. The company estimates that the lead time for Westovers is five days, over which time 500 units will be used in production. The cost of storing a unit is $22 per year including capital costs. A stockout is estimated to cost $4,200 for each day that the company must wait for shipment. Any time a stockout occurs, the company must wait until its sole supplier delivers these units.

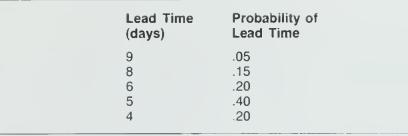

Over the past several years, the lead times have been as follows:

Other lead times have not occurred and may be ignored.

Required: Determine the most economic safety-stock level.

Step by Step Answer: