Evaluating cost of quality decisions T & W, an automotive parts manufacturer has expe- rienced an eight

Question:

Evaluating cost of quality decisions T & W, an automotive parts manufacturer has expe- rienced an eight percent rejection rate at its end-of-production inspection on its replacement headlights. Rejected units have no value and are discarded. In addition, three percent of the headlights are returned by stores, because they did not work. All returned headlights are exchanged for new ones without charge. The cost of handling, shipping, and clerical work associated with returned products averages 30% of the product selling price. During the current year the average production cost of units shipped is $9.00 each. The selling price of headlights is $10.50. The company's total production of headlights without regard to any defective units is 200,000 units.

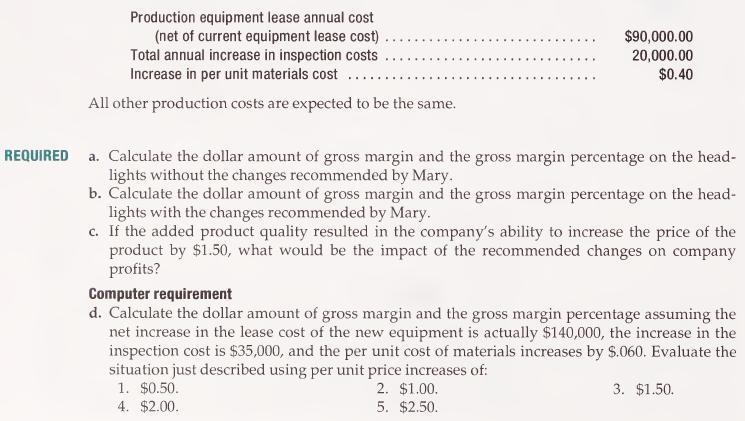

Mary, a production quality consultant, was hired by T & W to improve production quality and to improve the company's image for product quality. She suggests a program that requires some new production equipment, earlier inspections, and some higher quality materials. The new program is expected to reduce defects found in production to three percent and the number of returned units to one percent. The cost of the new program is as follows:

Step by Step Answer: