Stores pricing and calculation of EOQ and max./min. stock levels You have been appointed as inventory accountant

Question:

Stores pricing and calculation of EOQ and max./min. stock levels You have been appointed as inventory accountant to a company where material is a major element of cost. The chief accountant wants to instal an efficient material control and pricing system within the company and seeks your advice upon a number of issues:

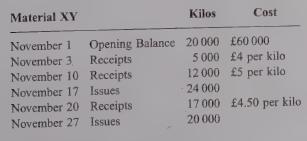

(a) Material XY has fluctuated in price over period 11 November 2003 and the chief accountant is unsure what price to cost the issues to job 124.

You are given the following information:

Required:

(i) Cost the issues on 17 November and 27 November to job 124 using two different methods of pricing. (6 marks)

(ii) On the assumption that the direct labour for job 124 is £50000 and overhead is recovered on the basis of 110% of direct material, calculate the selling price for job 124 if profit is 10% of selling price on the basis of the two methods that you selected in (i). (4 marks)

(iii) Comment critically upon the results that you have arrived at on the two methods used in (i) and (it).

(b) At the moment there are a number of stores spread throughout the factory, each duplicating the holding of stock. Stocktaking is carried out once a year, which requires the suspension of production for one week with overtime rates being paid to the stock checkers. The chief accountant maintains that the cost levels asso- ciated with the present system are too high and, with the planned growth of the company taken into consideration, a more efficient cost- effective system is required. Required: Evaluate (i) continuous stocktaking; (ii) centralized store keeping, as methods whereby the chief accountant's objectives (7 marks) can be met.

(c) The ordering of material KL has caused concern in the past, according to the chief accountant. There have been occasions when an excessive amount of stock has been carried beyond any possible demand, and when the - problem has been addressed and the stock level cut, orders have been unfulfilled and sales lost because the company has run out of material KL. The chief accountant has now said he wants a policy that achieves: (i) adequate stock of material KL, thus mini- mizing the risk of shortage and production dislocation, balanced with, (ii) avoidance of excessive stack levels of material KL and the consequent tying up of scarce funds. You are given the following information: (i) Budgeted average demand for material KL is 400 kilos per week and production is main- tained for 50 weeks in the year. (ii) The order cost is 150 per order.

(iii) The standard material cost of KL is £6 per kilo and carrying costs are 333% of that figure per annum for each kilo.

(iv) The maximum usage in any one week is 600 kilos and the minimum 400.

On average, the orders take anything from one to three weeks to be delivered after they have been placed.

Required:

In order to meet the chief accountant’s objectives, what is:

(i) the optimum order quantity that should be placed?

(ii) the re-order level for stock of KL?

(iii) the minimum level of stock that should be held?

(iv) the maximum level of stock that should be held?LO1

Step by Step Answer: