Riobamba Manufacturing produces specially machined parts. The parts are produced in batches in one continuous manufacturing process.

Question:

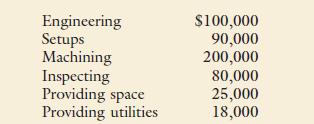

Riobamba Manufacturing produces specially machined parts. The parts are produced in batches in one continuous manufacturing process. Each part is custom produced and requires special engineering design activity (based on customer specifications). Once the design is completed, the equipment can be set up for batch production. Once the batch is completed, a sample is taken and inspected to see if the parts are within the tolerances allowed. Thus, the manufacturing process has four activities: engineering, setups, machining, and inspecting. In addition, there is a sustaining process with two activities:

providing utilities (plantwide) and providing space. Costs have been assigned to each activity using direct tracing and resource drivers as follows:

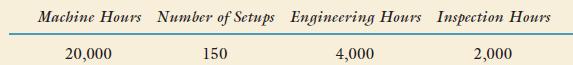

Activity drivers for each activity have been identified and their expected usage listed as follows:

The costs of facility-level activities are assigned using machine hours.

Required:

1. Identify the activities within each process as unit-level, batch-level, product-level, or facility-level.

2. Create an activity relational table that can be used to calculate activity rates.

3. Using the information in the activity relational table, calculate activity rates.

Step by Step Answer:

Cost Management Accounting And Control

ISBN: 9780324233100

5th Edition

Authors: Don R. Hansen, Maryanne M. Mowen