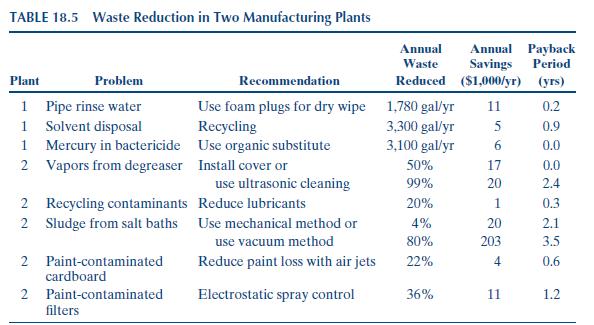

In an EPA-funded project, teams conducted waste minimization assessments of several medium-sized manufacturing plants. Table 18.5 provides

Question:

In an EPA-funded project, teams conducted waste minimization assessments of several medium-sized manufacturing plants. Table 18.5 provides a breakdown of the measures for two plants, the first a paint factory and the second a factory producing oil coolers for heavy equipment. The engineering teams’ recommendations ranged from simple

‘‘housekeeping’’ measures, such as putting a lid on a degreasing tank, to more complex process innovations, such as switching from a solvent-based to a vacuum-cleaning method. For the two plants, waste reduction ranged from 4% to 99%, while the average payback period was well under one year. The biggest waste reducers also generate the largest annual savings—for example, using ultrasonic degreasing in plant.

And even though such measures have the longest payback periods, they are probably the most profitable investments because of the large cost savings.

1. Is ‘‘waste reduction’’ a clean technology?

2. If we believe the evidence in this table, why are these manufacturing firms leaving money on the table? Why don’t waste reduction survey companies make a living consulting with companies to show them how to cut pollution and make money at the same time?

Step by Step Answer: