The plasma spray-coating process of Problem 5.25 can be used to produce nanostructured ceramic coatings. Such coatings

Question:

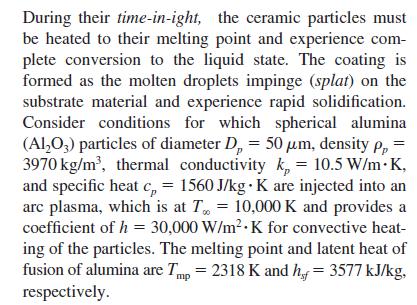

The plasma spray-coating process of Problem 5.25 can be used to produce nanostructured ceramic coatings. Such coatings are characterized by low thermal conductivity, which is desirable in applications where the coating serves to protect the substrate from hot gases such as in a gas turbine engine. One method to produce a nanostructured coating involves spraying spherical particles, each of which is composed of agglomerated Al2O3 nanoscale granules. To form the coating, particles of diameter Dp = 50 μm must be partially molten when they strike the surface, with the liquid Al2O3 providing a means to adhere the ceramic material to the surface, and the unmelted Al2O3 providing the many grain boundaries that give the coating its low thermal conductivity. The boundaries between individual granules scatter phonons and reduce the thermal conductivity of the ceramic particle to kp = 5W/m · K. The density of the porous particle is reduced to 3800 kg/m3. All other properties and conditions are as specified in Problem 5.25.

(a) Determine the time-in-flight corresponding to 30% of the particle mass being melted.

(b) Determine the time-in-flight corresponding to the particle being 70% melted.

(c) If the particle is traveling at a velocity V = 35 m/s, determine the standoff distances between the nozzle and the substrate associated with your answers in parts (a) and (b).

Data From Problem 5.25

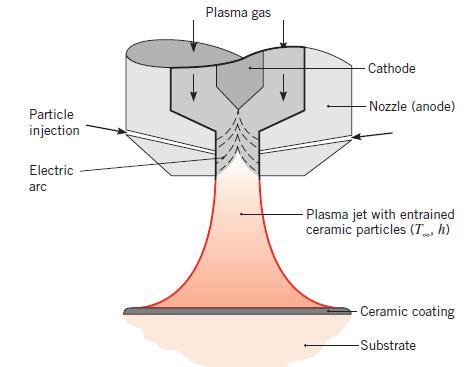

Plasma spray-coating processes are often used to provide surface protection for materials exposed to hostile environments, which induce degradation through factors such as wear, corrosion, or outright thermal failure. Ceramic coatings are commonly used for this purpose. By injecting ceramic powder through the nozzle (anode) of a plasma torch, the particles are entrained by the plasma jet, within which they are then accelerated and heated.

Step by Step Answer:

Fundamentals Of Heat And Mass Transfer

ISBN: 9780470501979

7th Edition

Authors: Theodore L. Bergman, Adrienne S. Lavine, Frank P. Incropera, David P. DeWitt