The immobilized enzyme layer shown in the figure below is designed to convert substrate A to product

Question:

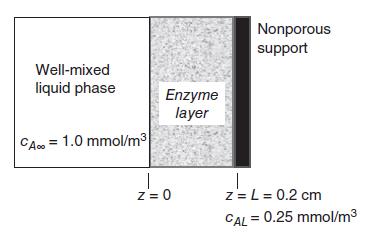

The immobilized enzyme layer shown in the figure below is designed to convert substrate A to product B according to the simplified reaction A → B with simplified rate equation RA = –kcA. In this process, the steady-state concentrations of substrate A in the bulk liquid and the interface between the enzyme layer and its inert support surface were measured, with cA∞ = 1.0 mmol/m3 at z = 0, and cAL = 0.25 mmol/m3 at z = L. The effective diffusion coefficient of substrate A within the enzyme layer is DAe = 2.0 X 10–5 cm2/s, and the thickness of the immobilized enzyme layer is L 0.2 cm. The surrounding fluid is well mixed, and the concentration of substrate A at the surface of the enzyme layer can be taken as the bulk concentration of substrate A in the surrounding liquid.

a. What are valid boundary conditions for this process?

b. Based on the measured values for cA∞ and cAL, what is the first-order rate constant k?

c. If the total exposed surface area of the enzyme layer is S = 2.0 m2, what is the production rate of product B?

d. Based on your calculation of the Thiele modulus, is the process reaction controlled, diffusion controlled, or neither?

Step by Step Answer:

Fundamentals Of Momentum Heat And Mass Transfer

ISBN: 9781119723547

7th Edition

Authors: James Welty, Gregory L. Rorrer, David G. Foster