During the paired-comparison experiment evaluating tool wear (Example 3.3), parts were selected from each lot to evaluate

Question:

During the paired-comparison experiment evaluating tool wear

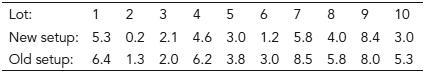

(Example 3.3), parts were selected from each lot to evaluate the variability of a specified dimension. The quality manager was concerned that the new setup procedure might affect the variability of the initial parts produced. A subgroup of five parts was selected during the first half-hour from each lot for each of the setup procedures. The dimension (in thousandths of an inch from nominal)

was measured for each part, and the range of the five parts was calculated. The following results (range, in thousandths of an inch)

were obtained:

Prepare run charts of the ranges and the adjusted ranges. Partition the variation in the ranges among the factor, background variable, and the nuisance variables.

Prepare run charts of the ranges and the adjusted ranges. Partition the variation in the ranges among the factor, background variable, and the nuisance variables.

Step by Step Answer:

Quality Improvement Through Planned Experimentation 3/E

ISBN: 978-0071759663

3rd Edition

Authors: Ronald Moen ,Thomas W Nolan ,Lloyd P Provost