Reconsider the heat sink in Prob. 975. In order to enhance heat transfer, a shroud (a thin

Question:

Reconsider the heat sink in Prob. 9–75. In order to enhance heat transfer, a shroud (a thin rectangular metal plate) whose surface area is equal to the base area of the heat sink is placed very close to the tips of the fins such that the interfin spaces are converted into rectangular channels. The base temperature of the heat sink in this case was measured to be 108°C. Noting that the shroud loses heat to the ambient air from both sides, determine the average natural convection heat transfer coefficient in this shrouded case. (For complete details, see Çengel and Zing, 1987.)

Data from problem 75

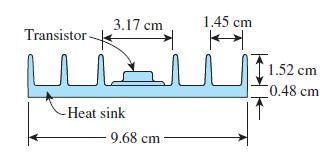

Aluminum heat sinks of rectangular profile are commonly used to cool electronic components. Consider a 7.62-cm-long and 9.68-cm-wide commercially available heat sink whose cross section and dimensions are as shown in Fig. P9–75. The heat sink is oriented vertically and is used to cool a power transistor that can dissipate up to 125 W of power. The back surface of the heat sink is insulated. The surface of the heat sink are untreated, and thus they have a low emissivity (under 0.1). Therefore, radiation heat transfer from the heat sink can be neglected. During an experiment conducted in room air at 22°C, the base temperature of the heat sink was measured to be 120°C when the power dissipation of the transistor was 15 W. Assuming the entire heat sink to be at the base temperature, determine the average natural convection heat transfer coefficient for the case.

Step by Step Answer:

Heat And Mass Transfer Fundamentals And Applications

ISBN: 9780073398181

5th Edition

Authors: Yunus Cengel, Afshin Ghajar