Repeat Problem 5.11, but design for a liquid rate 2.0 times the minimum and (60 %) of

Question:

Repeat Problem 5.11, but design for a liquid rate 2.0 times the minimum and \(60 \%\) of the flooding velocity.

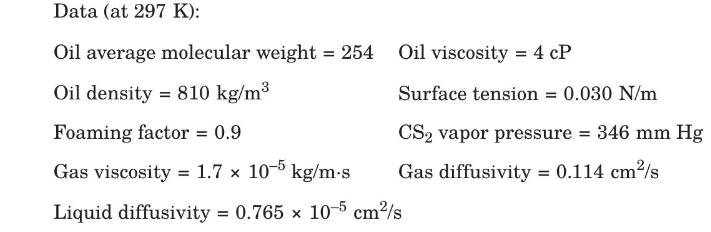

Data From Problem 5.11:-

Carbon disulfide, \(\mathrm{CS}_{2}\), used as a solvent in a chemical plant, is evaporated from the product in a dryer into an inert gas (essentially \(\mathrm{N}_{2}\) ) in order to avoid an explosion hazard. The \(\mathrm{CS}_{2}-\mathrm{N}_{2}\) mixture is to be scrubbed with an absorbent hydrocarbon oil (octadecane, \(\mathrm{C}_{18} \mathrm{H}_{38}\) ). The gas will flow at the rate of \(0.4 \mathrm{~m}^{3} / \mathrm{s}\) at \(297 \mathrm{~K}\) and \(1 \mathrm{~atm}\). The partial pressure of \(\mathrm{CS}_{2}\) in the original gas is \(50 \mathrm{~mm} \mathrm{Hg}\), and the \(\mathrm{CS}_{2}\) concentration in the outlet gas is not to exceed \(0.5 \%\). The oil enters the absorber essentially pure at a rate 1.5 times the minimum, and solutions of oil and \(\mathrm{CS}_{2}\) follow Raoult's law. Design a sieve-tray tower for this process. Design for a gas velocity which is \(70 \%\) of the flooding velocity. Assuming isothermal operation, determine

(a) Liquid flow rate, \(\mathrm{kg} / \mathrm{s}\).

(b) The tower diameter and plate spacing.

(c) The details of the tray design.

(d) Number of real trays required.

(e) Total gas-pressure drop.

Step by Step Answer: