Make or buy, activity-based costing, opportunity costs. (N. Melumad and S. Reichelstein, 1. Difference in relevant costs,

Question:

Make or buy, activity-based costing, opportunity costs. (N. Melumad and S. Reichelstein, 1. Difference in relevant costs, adapted) Ace Bicycle Company produces bicycles. This year’s expected production is 10,000 units.

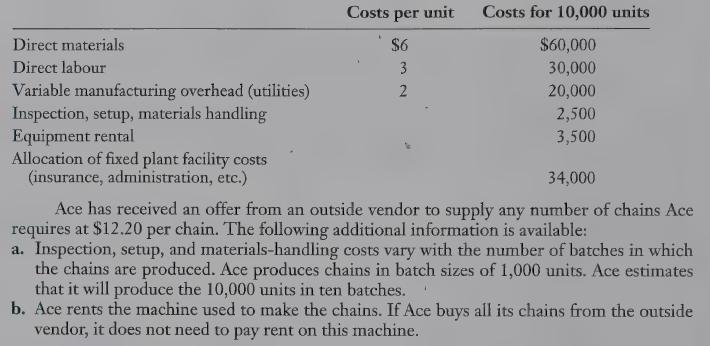

$6,000 Currently, Ace makes the chains for its bicycles. Ace’s accountant reports the following costs for making the 10,000 bicycle chains:

REQUIRED 1. Assume that, if Ace purchases the chains from the outside supplier, the facility where the chains are currently made will remain idle. Should Ace accept the outside supplier's offer at the anticipated production (and sales) volume of 10,000 units?

2. For this question, assume that if the chains are purchased outside, the facilities where the chains are currently made will be used to upgrade the bicycles by adding mud flaps and reflectors. As a consequence, the selling price on bicycles will be raised by $25. The variable per-unit cost of the upgrade would be $20.50, and additional tooling costs of $18,500 would be incurred. Should Ace make or buy the chains, assuming that 10,000 units are produced (and sold)?

3. The sales manager at Ace is concerned that the estimate of 10,000 units may be high and believes that only 6,400 units will be sold. Production will be cut back, and this opens up work space, which can be used to add the mud flaps and reflectors whether Ace goes outside for the chains or makes them in-house. At this lower output, Ace will produce the chains in eight batches of 800 units each. Should Ace purchase the chains from the outside vendor?

LO1

Step by Step Answer:

Cost Accounting A Managerial Emphasis

ISBN: 9780135004937

5th Canadian Edition

Authors: Charles T. Horngren, Foster George, Srikand M. Datar, Maureen P. Gowing