C4.44 LO 4.1 4.6 Product costing: engineering business Kilbirnie Fabrications (KF) is the fabrications division of a

Question:

C4.44 LO 4.1 4.6 Product costing: engineering business Kilbirnie Fabrications (KF) is the fabrications division of a sizeable engineering business operating from well-equipped premises in Kilbirnie, Wellington. Currently, KF employs two highly skilled expert fitters and three junior fitters, who are still building up their skills. KF's owner and manager, Fred Ferrous, is finding it tough, because increased competition is reducing his sales revenues and profit margins. He explains the problem: There are too many one-man bands who undercut my quotes and take away all the basic fabrication work; for example, the bolted fabrications that can be completed entirely by junior fitters. How can they charge such ridiculously low prices and stay in business? KF mostly wins complex fabrication work that requires expert welding by our expert fitters. Consequently, my expert fitters are overworked but my junior fitters are not fully occupied. Fred finds it difficult to hire expert fitters and usually trains his own from his pool of junior fitters. However, this takes time and there are considerable training costs involved. He cannot afford these unless the business becomes more profitable. He is worried that his overworked expert fitters might look for less stressful jobs elsewhere and that he needs to win more basic fabrication work in order to avoid making one of his junior fitters redundant. Fred explains his job costing and quoting system: The prospective customer's requirements are reviewed by an expert fitter, who estimates the likely direct labour times (of both expert and junior fitters) and costs the necessary materials. There is one composite hourly rate to cover all direct labour costs and a second hourly rate to cover overheads (welding equipment costs, establishment expenses and administrative costs). A 25 per cent markup on full cost (average for the industry) is applied to arrive at the quoted price. The composite direct labour cost rate and the predetermined overhead rate were calculated from KF's annual budget (Table 1).

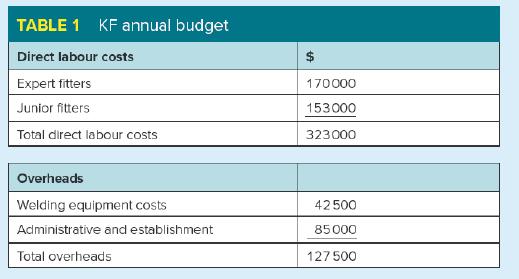

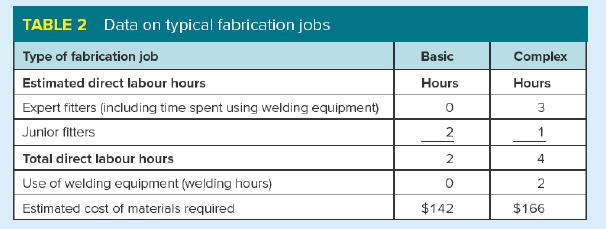

The total amount of chargeable fabrication work was estimated as follows: Expert fitters Junior fitters Total chargeable direct labour hours Estimated total usage of welding equipment 3400 hours 5100 hours 8500 hours 2125 welding hours Only the expert fitters are sufficiently qualified to use the welding equipment. Administrative and establishment overheads are very general in nature and are needed to support all types of fabrication work, roughly in proportion to the total labour hours of each job. Data on the type of basic fabrication job KF normally loses to the competition at the quotation stage and the type of complex fabrication job KF normally wins on quotation are provided in Table 2.

Required 1. Briefly explain why Fred Ferrous needs a product costing system at KF. 2. Calculate the composite direct labour cost rate and the predetermined overhead rate used by KF in the current costing system, and show how they are used to arrive at the full job cost and quoted price for the typical basic and complex fabrication jobs. 3. Stating your reasons, suggest an alternative job costing approach that would provide more accurate job costs and hence more appropriate quotes to prospective KF customers. Calculate the necessary labour rates and predetermined overhead rates. 4. Use your suggested alternative job costing system to provide the revised full job cost and quoted price for the typical basic and complex fabrication jobs. Highlight and explain the differences from the previous job costing system. 5. Advise Fred on the most appropriate job costing system for KF to use, stating your supporting reasons. (Ken Bates, Victoria Business School)

Step by Step Answer:

Management Accounting Information For Creating And Managing Value

ISBN: 9781743767603

9th Edition

Authors: Kim Langfield Smith, David Smith, Paul Andon, Ronald W. Hilton