Comparison of two costing systems The Redwood City plant of Crimson Components Company makes two types of

Question:

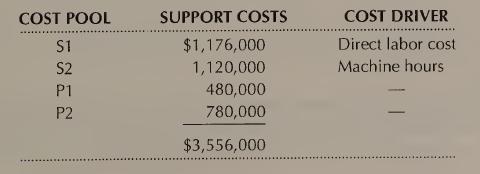

Comparison of two costing systems The Redwood City plant of Crimson Components Company makes two types of rotators, R361 and R572, for auto¬ mobile engines. The old cost accounting system at the plant traced support costs to four cost pools:

Poo! SI included service activity costs related to setups, production scheduling, plant administration, janitorial services, materials handling, and shipping. Pool S2 included activity costs related to machine maintenance and repair, rent, insurance, power, and utilities. Pools PI and P2 included supervi¬ sors' wages, idle time, and indirect materials for the two production depart¬ ments, casting and machining, respectively.

The old accounting system allocated support costs in Pools SI and S2 to the two production departments using direct labor cost and machine hours, respec¬ tively, as the cost drivers. Then the accumulated support costs in pools PI and P2 were applied to the products on the basis of direct labor hours. A separate rate was determined for each of the two production departments. The direct labor wage rate is $15 per hour in casting and $18 per hour in machining.

REQUIRED

(a) Determine the product costs per unit using the old system. Show all inter¬ mediate steps for allocations, including departmental cost driver rates and a breakdown of product costs into each of their components.

(b) Determine the product costs per unit using the new system.

(c) Explain the intuitive reason that the product costs differ under the two ac¬ counting systems.

(d) What should Crimson Components do to improve the profitability of its Redwood City plant?

(e) Describe how experienced production and sales managers are likely to react to the new product costs.

Step by Step Answer:

Management Accounting

ISBN: 9780130101952

3rd Edition

Authors: Anthony A. Atkinson, Robert S. Kaplan, S. Mark Young, Rajiv D. Banker, Pajiv D. Banker