K-Moss Bags and Shoes is a leading manufacturer of handbags, shoes and belts. The festive season is

Question:

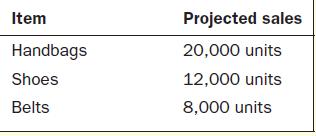

K-Moss Bags and Shoes is a leading manufacturer of handbags, shoes and belts. The festive season is around the corner, and the demand for these products is going to be higher than usual. Leather is the most important raw material for K-Moss. K-Moss uses the same leather for the manufacture of all products. The company has made the sales forecasts for each quarter at the beginning of the year, taking last year’s sales as the basis and tweaking them using relevant key performance indicators (KPIs). The forecasted sales for the upcoming holiday season are as follows:

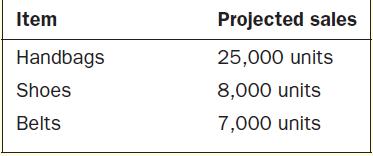

As the holiday season nears and K-Moss gets ready to step up production in its facilities, the management accountants realize that the sales forecast for this period is erroneous because the sales team and the senior management used the wrong metrics (KPIs) to forecast. The management team assumes the task of preparing a revised forecast. The new sales forecast for the holiday season is as follows:

K-Moss has set up three facilities for the manufacture of its final products in three different locations. Each of these three facilities maintains its own information system providing the details on raw material inventories, work-in-progress inventories and finished goods. Because of this arrangement, the company does not have a comprehensive view of the inventories at its facilities. Management is reluctant to change this setup because this decentralization of control has its own advantages and because setting up a new standardized management information system would require a substantial investment. Since the management accountants of the company lacked an overall view of the raw material inventory at the three facilities, they could not redeploy the available resources efficiently to meet the production targets for the revised sales forecast. The substantial loss of potential revenue during the holiday season has forced the company to examine its information systems. The board realizes that maintaining control over inventory is essential; it wants to start the process of implementing a standardized management information system at the earliest. This move is being vehemently opposed by K-Moss’s HR Director and its IT Director. The company has decided to change some of its processes to root out inefficiencies and streamline its processes. Earlier, whenever a workstation completed its work, the partially completed goods were moved forward to the next workstation regardless of whether that workstation needed them at that point or not. The result was an unintentional piling of work-in-progress inventory that may not have been completed for days. K-Moss was following the optimization approach of traditional inventory management. It purchased 60,000 units of raw materials annually. Under this model, the cost of ordering was £25 per order. The cost of carrying per unit of leather was £2.5 per year and lead time was 1 month. K-Moss has decided to shift from this model to a model of inventory management where the final assembly stage sends a signal to the preceding workstation specifying the exact amount of materials that will be needed over the next few hours to assemble products to fill customer orders.

Required

1. K-Moss has decided to implement enterprise resource planning (ERP) software to automate its management information system. List two characteristics of ERP systems.

2. K-Moss has incurred substantial losses during the holiday season. Hence, it has decided to implement an ERP system to maintain control over its inventory. Explain what the ERP process-oriented information system is based on.

3. K-Moss has decided to implement an ERP system to root out inefficiencies and streamline its processes. List one major problem with ERP systems.

4. Explain when K-Moss would be able to gain significant benefits from the automation of management information systems using the ERP software.

5. Prior to installing the new inventory management approach, which approach was K-Moss following?

6. Determine if K-Moss would be able to increase throughput time, which would result in substantial output and swift response to customers.

7. Through the shift in the inventory management system and the implementation of ERP, which approach is K-Moss aiming to move towards?

8. Calculate the economic order quantity (EOQ) and reorder point for K-Moss for the previous year using the previous year’s inventory management approach.

Step by Step Answer:

Management Accounting

ISBN: 9780077185534

6th Edition

Authors: Will Seal, Carsten Rohde, Ray Garrison, Eric Noreen