Myron Metal Works uses a small casting in one of its finished products. The castings are purchased

Question:

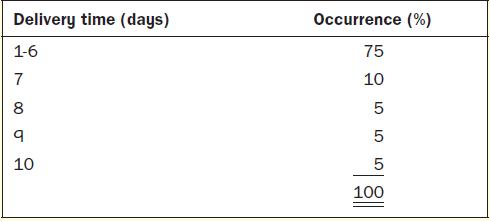

Myron Metal Works uses a small casting in one of its finished products. The castings are purchased from a foundry located in another state. In total, Myron Metal Works purchases 54,000 castings per year at a cost of £8 per casting. The castings are used evenly throughout the year in the production process on a 360-dayper- year basis. The company estimates that it costs £90 to place a single purchase order and about £3 to carry one casting in inventory for a year. The high carrying costs result from the need to keep the castings in carefully controlled temperature and humidity conditions, and from the high cost of insurance. Delivery from the foundry generally takes 6 days, but it can take as long as 10 days. Delivery time in days and rate of occurrence (as a percentage) are shown in the following table:

Required

1. Compute the economic order quantity (EOQ).

2. Assume that the company is willing to assume a 15% risk of being out of stock. What would be the safety inventory? The reorder point?

3. Assume that the company is willing to assume only a 5% risk of being out of stock. What would be the safety inventory? The reorder point?

4. Assume a 5% risk of being out of stock, as described in Requirement 3. What would be the total cost of ordering and carrying inventory for one year?

5. Refer to the original data. Assume that by using process re-engineering the company reduces its cost of placing a purchase order to only £6. Also, the company estimates that, when the waste and inefficiency caused by inventories are considered, the true cost of carrying a unit in inventory is £7.20 per year.

(a) Compute the new EOQ.

(b) How frequently would the company be placing an order, as compared to the old purchasing policy?

Step by Step Answer:

Management Accounting

ISBN: 9780077185534

6th Edition

Authors: Will Seal, Carsten Rohde, Ray Garrison, Eric Noreen