Pasadena Chemical Company manufactures a wide range of chemical compounds. One of the most difficult compounds is

Question:

Pasadena Chemical Company manufactures a wide range of chemical compounds. One of the most difficult compounds is a cleaning solvent made from an expensive and volatile raw material, tetrax, that is often in short supply. The company uses 1 liter of tetrax for every 100 liters of cleaning solvent it makes.

Tetrax costs \(\$ 560\) per liter and must be stored in space leased in a special warehouse. The storage cost including all related costs is \(\$ 2\) per liter per day stored. The chemical is unstable, and the loss on average is \(1 \%\) of the volume stored per day. The cleaning compound can also be made from monax, which costs \(\$ 1,000\) per liter. Because of the prohibitive cost of monax, however, Pasadena avoids using it unless it is absolutely necessary.

The three existing tetrax suppliers have been unreliable. For this reason, Pasadena has refused to begin production of the cleaning compound. Recently, a new supplier joined the field and guarantees the supply of tetrax under three conditions: (1) Customers must be prepared to take weekly deliveries of tetrax, (2) the weekly order must be for precisely the same quantity each week, and (3) the contract must cover 1 year. If these conditions are met, the supplier will replace any undelivered tetrax with monax.

Because the cleaning compound itself is also volatile, users demand the product when they are ready for it and no sooner. Suppliers carefully estimate the amount of cleaner they require and will not accept less than the ordered amount.

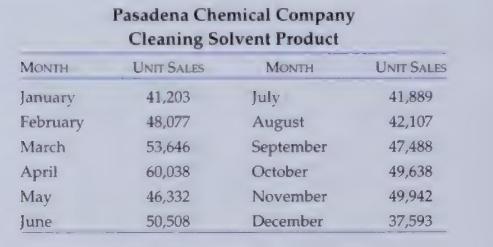

Following are the contracted cleaning compound sales for next year:

Required

a. Set up a spreadsheet for this problem. The spreadsheet should allow you to compute the total cost of a contract with the new supplier. This total cost includes purchase price, storage cost, and the cost, if necessary, of any monax that would be purchased. Set up the spreadsheet to allow you to easily vary the purchase quantity of tetrax. To simplify the problem, make the following assumptions:

• The loss each month is \(1 \%\) times the number of days in the month times the sum of (1) the average of the opening and ending inventory (before the loss), and (2) one-half the batch size.

• The cost of carrying inventory each month is two times the number of days in the month times the sum of (1) the average of opening and closing inventory (after the loss), and (2) one-half the batch size.

• Production takes place 7 days per week.

• January, March, July, and November have 35 days each; the rest of the months of the year have 28 days each.

b. What is the best weekly quantity to contract for purchase from the new supplier?

Step by Step Answer: