Product profitability analysis Kidspack, Inc., has recently expanded its line of LO 1, 3, 4, 5 backpacks

Question:

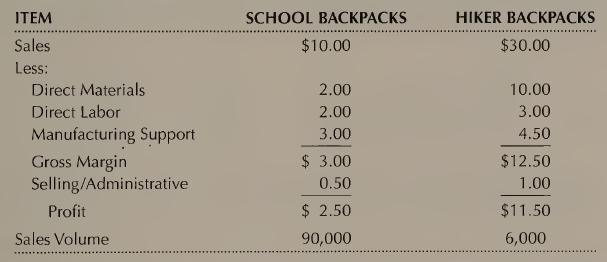

Product profitability analysis Kidspack, Inc., has recently expanded its line of LO 1, 3, 4, 5 backpacks to include high-quality, lightweight hiker backpacks. This new model uses more expensive material and takes longer to produce. While a basic school backpack can be cut and sewn together in 30 minutes, a hiker backpack takes 45 minutes to cut and sew together. The school model is produced in batches of 1000 packs while the hiker model is produced in batches of 100 packs. Each batch requires inspection time of one hour. Using direct labor hours to allocate manufacturing support costs, product profitability is analyzed as follows:

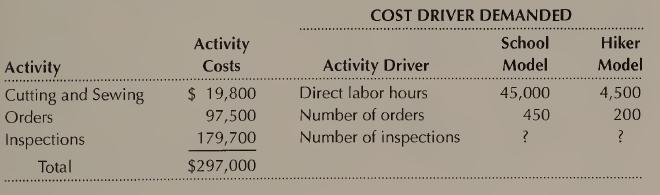

Angel Johnson, the controller at Kidspack, believes that activity-based cost¬ ing may be a more accurate way of measuring the costs of the two models. He has traced manufacturing support costs to the following activity pools.

REQUIRED

(a) The method of assigning costs to individual products does not affect the total manufacturing support costs. Only the amounts assigned to individual prod¬ ucts change. Explain why Angel should care about how support costs are as¬ signed to individual products.

Activity-Based Cost Management Systems 197

(b) Using activity-based costing, calculate the manufacturing support cost per unit for each of the two models.

(c) Analyze product profitability using activity-based costs.

Step by Step Answer:

Management Accounting

ISBN: 9780130101952

3rd Edition

Authors: Anthony A. Atkinson, Robert S. Kaplan, S. Mark Young, Rajiv D. Banker, Pajiv D. Banker