Single drivers versus multiple drivers Eagan Electrical Instruments Company estimates manufacturing support as (950 %) of direct

Question:

Single drivers versus multiple drivers Eagan Electrical Instruments Company estimates manufacturing support as \(950 \%\) of direct labor costs. Eagan's controller, Jim Chang, is concerned that the actual manufacturing support activity costs have differed substantially from the estimates in recent months. He suspects that the problem is related to the use of only one cost driver. Jim identified the following three additional cost drivers that reflect support activities: number of material moves, number of setups, and number of machine hours. He developed the following rates to estimate manufacturing support activity costs:

Multiple Cost Driver System

\(100 \%\) of direct labor cost

\$200 per move

\(\$ 300\) per setup

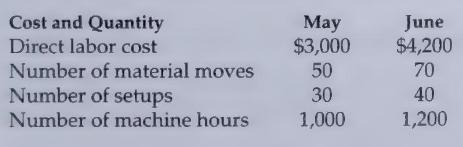

\(\$ 20\) per machine hour Information for 2 recent months includes the following:

Required

a. Estimate manufacturing support costs using the single-driver and multiple-driver systems.

b. Why do the two sets of estimates differ?

c. Why will both methods fail to predict accurately the manufacturing support costs? Is one of the two methods likely to be more useful than the other? Explain.

Step by Step Answer: