XY, a company that manufactures a range of timber products, is considering changing to a just-in-time (JIT)

Question:

XY, a company that manufactures a range of timber products, is considering changing to a just-in-time (JIT) production system.

Currently XY employs staff who are contracted to work and be paid for a total of 3 937.75 hours per month. Their labour efficiency ratio is 96 per cent and, as a result, they are able to produce 3780 standard hours of output each month in normal working hours.

Overtime working is used to meet additional demand, though the management of XY try to avoid the need for this because it is paid at a 50 per cent premium to the normal hourly rate of \($10\) per hour.

Instead, XY plan production so that in months of lower demand inventory levels increase to enable sales demand to be met in other months. XY has determined that the cost of holding inventory is \($6\) per month for each standard hour of output that is held in inventory.

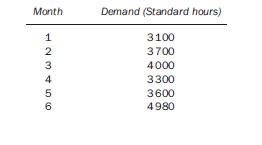

XY has forecast the demand for its products for the next six months as follows:

You may assume that all production costs (other than labour) are either fixed or are not driven by labour hours worked, and that there is zero inventory at the start of month 1 and at the end of month 6.

Assume also that production and sales occur evenly during each month at present, and that the minimum contracted hours will remain the same with the JIT system.

Required

(a) With the current production system,

(i) Calculate for each of the six months and the period in total, the total inventory holding costs.

(ii) Calculate the total production cost savings made by changing to a JIT production system.

(b) Explain TWO other factors that should be considered by XY before changing to a JIT production system.

Step by Step Answer: