Advanced: Optimal output using the graphical approach and the impact of an increase in capacity A company

Question:

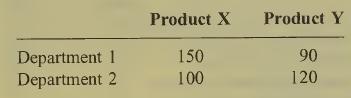

Advanced: Optimal output using the graphical approach and the impact of an increase in capacity A company makes two products, X and Y. Product X has a contribution of £124 per unit and product Y £80 per unit. Both products pass through two departments for processing and the times in minutes per unit are:

Currently there is a maximum of 225 hours per week available in department 1 and 200 hours in department 2. The company can sell all it can produce of X but EEC quotas restrict the sale of Y to a maximum of 75 units per week.

The company, which wishes to maximize contri¬ bution, currently makes and sells 30 units of X and 75 units of Y per week.

The company is considering several possibilities including (i) altering the production plan if it could be proved that there is a better plan than the current one;

(ii) increasing the availability of either department 1 or department 2 hours. The extra costs involved in increasing capacity are £0.5 per hour for each department;

(iii) transferring some of their allowed sales quota for Product Y to another company. Because of commitments the company would always retain a minimum sales level of 30 units.

You are required to

(a) calculate the optimum production plan using the existing capacities and state the extra contribution that would be achieved compared with the existing plan; (8 marks)

(b) advise management whether they should increase the capacity of either department 1 or department 2 and, if so, by how many hours and what the resulting increase in contribution would be over that calculated in the improved production plan. (7 marks)

(c) calculate the minimum price per unit for which they could sell the rights to their quota, down to the minimum level, given the plan in

(a) as a starting point.

Step by Step Answer: