Noguchi Company manufactures cooling systems. Noguchi produces all the parts necessary for its product except for one

Question:

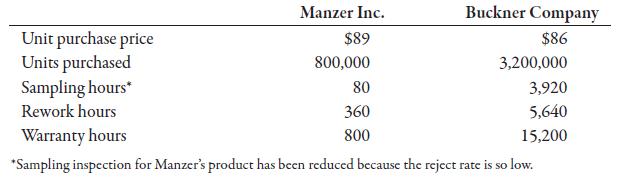

Noguchi Company manufactures cooling systems. Noguchi produces all the parts necessary for its product except for one electronic component, which is purchased from two local suppliers: Manzer Inc. and Buckner Company. Both suppliers are reliable and seldom deliver late; however Manzer sells the component for $89 per unit, while Buckner sells the same component for $86.Bowman purchases 80% of its components from Buckner because of its lower price. The total annual demand is 4,000,000 components. To help assess the cost effect of the two components, the following data were collected for supplier-related activities and suppliers:

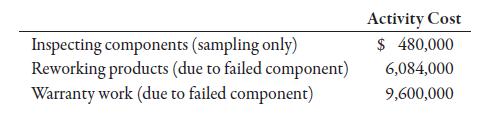

I. Activity Data

II. Supplier Data

Required:

1. Calculate the cost per component for each supplier, taking into consideration the costs of the supplier-related activities and using the current prices and sales volume.

2. Suppose that Noguchi loses $4,000,000 in sales per year because it develops a poor reputation due to defective units attributable to failed components. Using warranty hours, assign the cost of lost sales to each supplier. By how much would this change the cost of each supplier’s component? (Round to two decimal places.)

3. Based on the analysis in Requirements 1 and 2, discuss the importance of activity-based supplier costing for internal decision making.

4. After assessing the cost of each supplier, Noguchi’s management decided to buy 3,200,000 components from Manzer, Inc. and 800,000 components from Buckner Company, the exact opposite of current policy. Noguchi estimated that this change would quadruple the demands of the supplier-related activities for Manzer, Inc. and that it would reduce the same demands by 75% for Buckner Company. Noguchi also estimated that the new costs of the supplier-related activities would be as follows:

Inspecting: $ 130,000

Reworking: $2,850,000

Warranty work: $3,500,000

Lost sales: $2,100,000

Repeat the calculations of Requirements 1 and 2, using the same unit purchase prices. Assuming an Excel program was created for the initial analysis, identify the critical equations needed to support data analysis, and comment on the power and utility of data analytics.

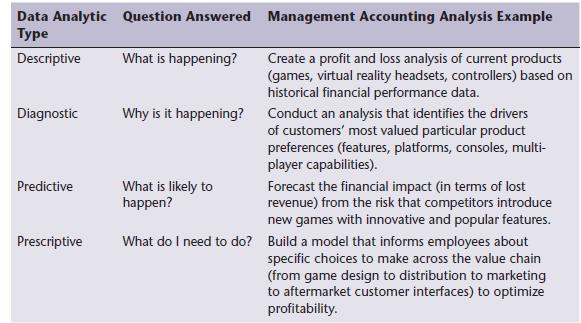

5. If Noguchi makes the changes described in Requirement 4, what are the projected savings when compared to its current purchasing policy? Would a new Excel equation facilitate answering this question? Review the data analytic types presented in Exhibit 2.2. Which of the four types plays the principal role in the analysis of Requirement 4? 1. Supplier cost:

1. Supplier cost:

First, calculate the activity rates for assigning costs to suppliers:

Inspecting components:

$480,000/4,000 sampling hours = $120 per sampling hour

Reworking products:

$6,084,000/6,000 rework hours = $1,014 per rework hour

Warranty work:

$9,600,000/16,000 warranty hours = $600 per warranty hour

Next, calculate the cost per component by supplier:

Step by Step Answer:

Managerial Accounting The Cornerstone Of Business Decision Making

ISBN: 9780357715345

8th Edition

Authors: Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger