Question: DP13.5 Plastic extrusion is a well-established method widely used in the polymer processing industry [12]. Such extruders typically consist of a large barrel di vided

DP13.5 Plastic extrusion is a well-established method widely used in the polymer processing industry [12].

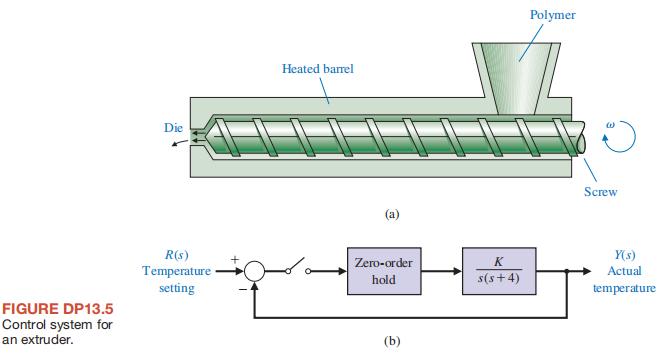

Such extruders typically consist of a large barrel di

vided into several temperature zones, with a hopper at one end and a die at the other. Polymer is fed into the barrel in raw and solid form from the hopper and is pushed forward by a powerful screw. Simultaneously, it is gradually heated while passing through the var

ious temperature zones set in gradually increasing temperatures. The heat produced by the heaters in the barrel, together with the heat released from the friction between the raw polymer and the surfaces of the barrel and the screw, eventually causes the melt

ing of the polymer, which is then pushed by the screw out from the die, to be processed further for various purposes.

The output variables are the outflow from the die and the polymer temperature. The main controlling variable is the screw speed, since the response of the process to it is rapid.

The control system for the output polymer tem

perature is shown in Figure DP13.5. Select a gain K

and a sampling period T to obtain a percent overshoot of P O. . ≤ 20% and Ts ≤ 10 s for a unit step input.

FIGURE DP13.5 Control system for an extruder. Die Heated barrel (a) Polymer Screw R(s) Temperature Zero-order hold K s(s+4) Y(s) Actual setting temperature (b)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts