a. What are the aggregate demand forecast and aggregate safety stock for each week, and the aggregate

Question:

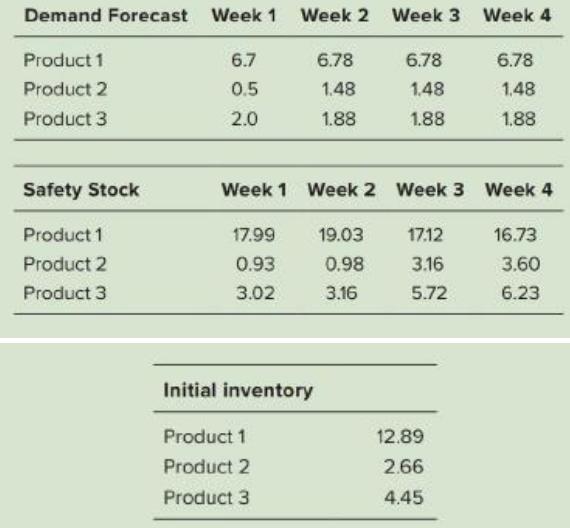

a. What are the aggregate demand forecast and aggregate safety stock for each week, and the aggregate initial inventory?

b. Using the result of part a, and available hours during regular time (80 hours per week) and overtime (36 hours per week), production rate of 1.14 hours per unit, setup time of eight hours, holding cost per unit per week of $150, setup cost of $400, and overtime cost of $212 per unit, and similar information about the other families, the linear programming software has determined the following quantities for this family for weeks 1 to 4: 11.14, 14.00, 10.34, and 10.70 units. What is the aggregate ending inventory in each week? Are they greater than or equal to the required aggregate safety stocks for each week?

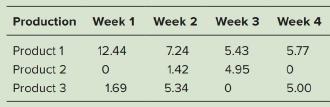

c. The aggregate production quantities are next disaggregated by also using linear programming for each family. Given the production rates and setup time for each product, and some other cost data, the linear programming software determines the production quantity for each product during the next four weeks in order to minimize the total cost of holding inventory and setup time and the deviation of total production quantity from that derived in the aggregate model for each week, such that after satisfying the demand, the ending inventories each week are greater than or equal to the required safety stocks. Using the aggregate production quantities given in part b, production rates of 1.10, 1.21, and 1.12 hours per unit for products 1 to 3, respectively, setup time of 0.5 hour for each production run, holding cost per unit per week of $150, and setup cost of $100 per product run, the linear programming software has determined the following quantities for each product for weeks 1 to 4. What are the ending inventories for each product in each week? Are they greater than or equal to the required safety stocks for each product in each week?

Welch's, a major producer of grape juice, packages a few families of the products on each line. In order to prepare the master production schedule, the planner first aggregates the demand and the required safety stock of each product in each family during the next four weeks. She also aggregates the initial inventory of each product to obtain the family initial inventory. Then, given the production hours available during the regular time and overtime, the production rates and the setup time for each family, and some other cost data, she uses a linear programming software to determine the production quantity of each family during the next four weeks in order to minimize the total cost of holding inventory, setup time, and overtime, such that after satisfying the demand, the ending inventories each week are greater than or equal to the required safety stocks.

On a particular line, four families are packaged. One of the families has three products in it. The forecast demand (in 1,000 cases), the safety stock, and the beginning inventory for each product during the next four weeks are as follows:

Step by Step Answer:

Operations Management

ISBN: 9781259270154

6th Canadian Edition

Authors: William J Stevenson, Mehran Hojati, James Cao