The Neptune Co. produces two models of aeration systems for aquariums: the Junior (J) and the Senior

Question:

The Neptune Co. produces two models of aeration systems for aquariums: the Junior

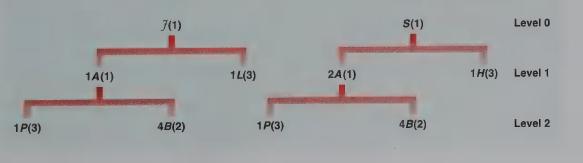

(J) and the Senior (S). The product structure trees for these products are shown below with the lead times to purchase or make each component shown in parentheses after the letter that stands for the component. The levels that the items would appear in the bill of materials are also indicated to the right for each level of product structure. The quantity of a component required to make one

unit of the next-higherlevel item is indicated to the left of the letter that stands for the component. The J requires one pump assembly (A) that attaches to one end of a low-capacity motor (L). The S requires two pump assemblies (A), one installed on each end of a higher-capacity motor (H). Each pump assembly (A) consists of a purchased pump kit that includes all the hoses and attachments (P) and four brackets to attach the pump to the motor (B).

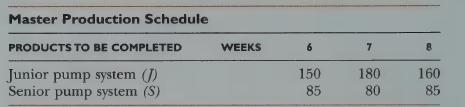

The longest lead time through any branch on the product structure trees is for the pump kits. The execution time for procurement and production on this branch is 1 + 1 + 3 = 5 weeks, so the company must complete plans for these products while the periods being planned are at least 6 weeks in the future. The master production schedule (MPS) for products J and S for weeks 6, 7, and 8 is shown below.

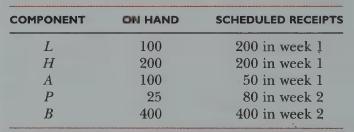

The following are the “on-hand” balances and “scheduled receipts” for the components of the company’s products:

(Note: In many actual applications of MRP, the time-phased inventory records for finished products and components would show requirements in the early periods and sufficient scheduled receipts to cover these requirements. Gross requirements and most of the scheduled receipts in the early periods have been omitted from this problem and many of the problems in this chapter because they add numbers that might obscure the objective of illustrating how a set of requirements from the master production schedule is transmitted to all the levels of components of the products. One scheduled receipt is shown for each component to show how these affect the on-hand balance.)

(a) Develop the time-phased inventory records for all of the components (L, H, A, F, and B) showing the numbers that result from the master production schedule, on-hand balances, and scheduled receipts that were given.

(b) Is there any indication that the Neptune Co. should take any action this week?

Step by Step Answer:

Operations Management Providing Value In Goods And Services

ISBN: 9780030262074

3rd Edition

Authors: Dilworth, James B