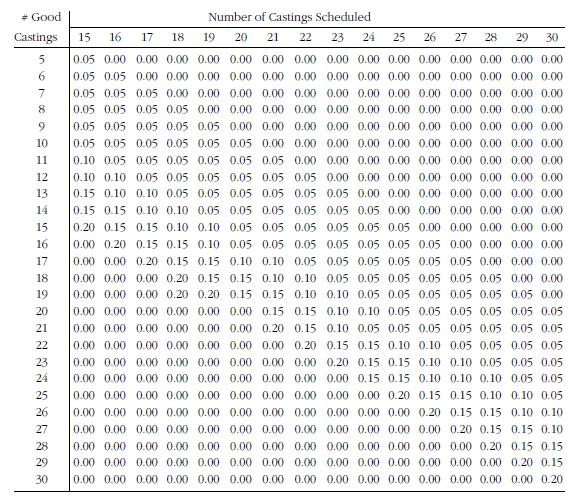

A foundry produces castings to order. An order for 20 special castings has been received. Since the

Question:

A foundry produces castings to order. An order for 20 special castings has been received.

Since the casting process is highly variable, not all castings produced are good. The cost of producing each casting is $550; the additional cost of finishing a good casting is $125. If a casting is not good, it is recycled at a value of $75; excess good castings are not finished but are recycled at a value of $75. The customer has agreed to accept 15, 16, 17, 18, 19, or 20 castings at a price of $1250 each. If fewer than 15 good castings are produced, none will be purchased by the customer. Probability distributions for the number of good castings produced in a batch of varying sizes are given below. How many castings should be scheduled in order to maximize expected profit?

Step by Step Answer:

Facilities Planning

ISBN: 9780470444047

4th Edition

Authors: James A. Tompkins, John A. White, Yavuz A. Bozer, J. M. A. Tanchoco