The Pelnor Corporation is the nations largest manufacturer of industrial-size washing machines. A main ingredient in the

Question:

The Pelnor Corporation is the nation’s largest manufacturer of industrial-size washing machines. A main ingredient in the production process is 8- by 10-foot sheets of stainless steel. The steel is used for both interior washer drums and outer casings.

Steel is purchased weekly on a contractual basis from the Smith-Layton Foundry, which, because of limited availability and lot sizing, can ship either 8,000 or 11,000 square feet of stainless steel each week. When Pelnor’s weekly order is placed, there is a 45% chance that 8,000 square feet will arrive and a 55% chance of receiving the larger size order.

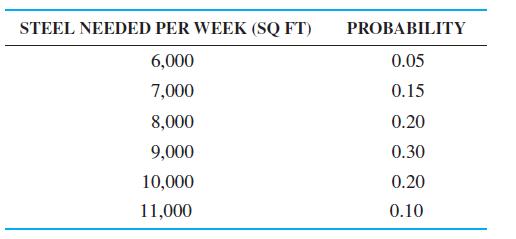

Pelnor uses the stainless steel on a stochastic

(nonconstant) basis. The probabilities of demand each week follow:

Pelnor has a capacity to store no more than 25,000 square feet of steel at any time. Because of the contract, orders must be placed each week regardless of the on-hand supply.

(a) Simulate stainless steel order arrivals and use for 20 weeks. (Begin the first week with a starting inventory of 0 stainless steel.) If an end-of-week inventory is ever negative, assume that back orders are permitted and fill the demand from the next arriving order.

(b) Should Pelnor add more storage area? If so, how much? If not, comment on the system.

Step by Step Answer:

Quantitative Analysis For Management

ISBN: 9781292217659

13th Global Edition

Authors: Barry Render, Ralph M. Stair, Michael Hanna, Trevor Hale