Question

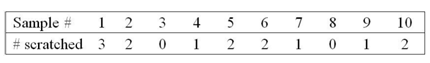

1. A producer of contact lenses regularly takes samples of 100 lenses and inspects them for scratches. If a lens has a single scratch, it

1. A producer of contact lenses regularly takes samples of 100 lenses and inspects them for scratches. If a lens has a single scratch, it cannot be sold. The results of 10 samples are shown below:

What sample is out of control?

2. The diameter of a mason jar is 3 inches but can be as large as 3.03 inches and as small as 2.97 inches. Samples of mason jars show that these components have a grand mean of 3.01 inches and a standard deviation of 0.02 inches. What is the probability of producing a bad product?

3. A product is made up of two subsystems in parallel. Subsystem one consists of ten elements in series each with a failure rate of 1/100. The second subsystem consists of 5 elements in series each with a failure rate of 1/200. What is the overall reliability of the system?

4. The upper and lower specifications for metal head plates are 5 +/- 0.1 cm. Samples of the metal head plate?s yields a process mean of 5.05. We know that the population standard deviation is 0.04. What is the population capability index?

Sample # 1 2 # scratched 3 2 3 0 4 1 52 6 2 7 1 8 0 9 1 10 2

Step by Step Solution

3.45 Rating (152 Votes )

There are 3 Steps involved in it

Step: 1

1 The lower limit is coming out ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started