Question

1. How important is it to have a mix of products? When shoes slack off during the winter, the apparel business picks up. What are

1. How important is it to have a mix of products? When shoes slack off during the winter, the apparel business picks up. What are the implications of seasonal products? What problems does this create for The Finish Line?

2. Spread of risk. Given the way the buying takes place for the shoe products, who is taking the most risk? Is it the manufacturer or the buyer?

3. Differences between stores. A particular store might be an A store for ethnic basketball, a B store for outdoor wear, and a C store for running. The buyer has the ability to assign the A, B, C ranking by department. They can even get down to a style-by-style ranking. How does this impact the management of inventory?

4. What changes would you suggest to the performance measures currently used?

The product is normally not replenished. Rather, the item is purchased, pushed out to the retail stores and sold. There are exceptions to this, particularly with staple items, such as socks. Determining the amount to be purchased can be difficult.

Even though it only takes two to three months for the company to actually produce the product, the normal lead-time quoted by a company like Nike or Reebok is six months. From the many choices presented, the buyer is faced with the difficult problem of anticipating what will be hot six to twelve months into the future. Imagine how difficult it is to anticipate the success of a Jordan or O?Neil during the next basketball season! The life of a new style is less than six months.

The order quantity is built up from forecasts of demand done at the store level. The actual distribution of sizes sold at each store is part of the calculation. These forecasts are then adjusted based on projected store department sales figures.

The supplier collects orders from buyers at all the major retail outlets using strict deadlines. Missing the forecast for an item can be disastrous, since there is normally no second chance to reorder. Ordering too many results in having to discount the item at one of the outlet stores where discontinued styles are sold.

Once the order arrives from the supplier, approximately 60 percent is immediately distributed to the stores. The allocation to the stores is calculated from the forecasts used to determine the original order, adjusted for store closings and new stores. The rest of the order is stored in the warehouse, and used to replenish store inventory.

Retail Store Inventory Replenishment

The central computer keeps a perpetual inventory of every stock keeping unit (SKU) at every store and in the warehouse. An SKU is a unique item in inventory. In the case of shoes, for example, an SKU is a specific style, color, and size pair of shoes. A typical store has approximately 5,000 SKUs and the Circle Center store has more than 10,000 SKUs.

Each night, the computer calls each store and downloads information concerning each sale to a customer, returns from a customer, receipts from the warehouse, and transfers to another store. The computer knows the exact location of each unit of each SKU sold by the Finish Line. If a store needs, for example, a size 10 means, black, Michael Jordan, basketball shoe, the system can be queried for the current location of a pair. The system keeps detailed sales history information to aid the buyers in their purchasing decisions.

Associated with each SKU at each location, a minimum and maximum quantity target is defined. These values are used to control the replenishment of inventory at each location. The system generates a replenishment order for a location whenever the on hand balance plus the amount in transit to that location is less than the minimum level. The size of the order is the quantity needed to bring the level up to the maximum amount.

For a typical style at a store there might only be 24 to 30 pairs and that can be spread over 12 or 13 sizes. For the largest and smallest sizes the minimum and maximum quantity typically would be set to one. The minimum and maximums might be two for the sizes other than the 9's to 11's, which might be set at a minimum of three and maximum of four.

Don Courtney commented on the first Friday of sales at the Circle Center store:

?...the first Friday we sold 286 pairs of men?s shoes and those represented 276 different SKUs. So it was all one of this, one of that, and one of this. And without having that broad range of offerings, obviously we wouldn?t be able to do that. So it?s very important when you have that kind of business, it?s very important that when you sell one, you can replace it.?

At some point, replenishment is no longer possible from the distribution center. At this time the buyers have to decide which stores will receive the remaining inventory. The buyers run what is called a grid sheet that shows store by store the recent sales and the sizes available for a style. From this they can see where the sizes are broken up and make transfers to stores where the style is selling well. Other factors the buyer must consider when making the transfers are the total number of shoes that a store can hold, the minimum number of shoes a store needs to have on hand to do business, the number of different styles on hand at the store, and the number of display locations at the store.

The Finish Line has a few stores that they refer to as close out or outlet stores. In these stores, shoes are displayed in large racks by size. So ultimately, when styles are broken to a point where all the sizes cannot be maintained in inventory, the style is closed out in these special stores.

The Layout of the Circle Center Store

The layout of the new store is typical of the other stores, just much larger. Along each wall are display ranks where a single shoe of each style is shown. These display racks are organized by men?s shoes, women?s shoes, hiking shoes, and golf shoes. There is a large display area for sports apparel in the rear of the store.

Other than for a few sale items, the inventory for each style is kept in a stock room that is adjacent to the store. Similar to the display racks, the stock room is organized by shoe style and by size within the style.

When a customer indicates an interest in a shoe, the salesperson goes to the stockroom to retrieve a pair. The shoes are brought back to the customer and fitted. If the customer wants the shoes, they are then purchased at the centralized cash register kiosk.

Don had some concerns with the organization of the Circle Center store:

?When we opened that store, we had plenty of everything in that first weekend, every time a salesperson left the shoe wall to go to the back room, you knew he or she was going to come back with the size that was requested. There?s going to come a day, even in the first weeks, when like everybody else, you?d never have everything. We?re always in the process of some styles fazing out.

Why that?s such a concern to me with Circle Center is that it?s a long walk, a walk all the way across the store. We keep our back room in an order. You put all the basketball shoes together so that if you go back for a particular basketball shoe, because that?s what the customer wanted, and we don?t have it in their size, you can find another basketball style in the same look, same price range, to come back and say, ?Well, I don?t have that, but I have this. Would you like this other shoe??

In fact, we have wired the columns in that store so that we could install a couple of touch screen terminals that could be used to quickly check store stock. We?ve even talked about doing headsets and having somebody in the back room checking, retrieving, and running the shoes to the shoe wall.?

Inventory Accuracy

Accuracy in the inventory system is extremely important to the successful operation of the Finish Line system. Each item that is picked from the distribution center is scanned to verify what was obtained. It is easy for mistakes to be made, though. For example, if the quantity asks for seven of a particular item, the picker can scan the item and quickly enter the quantity seven. If they are picking T-shirts, it is easy for an extra one to be there that they did not see. Even though they have the right item, the right size, the right SKU, the quantity is incorrect.

The orders for each store are batched and sent in cartons. The system knows what should be in each carton. Sometimes, though, items get sent to the wrong store due to sorting errors in the warehouse. On receipt, the store must verify that what the system thought was in the carton is actually in the carton. Mistakes can even be made at this point in the process. Stores only get credited with what they verify as having been received.

Don commented on the problem:

?But I?ll tell ya?, the times that we send ?em the biggest shipments are the times when they are the most crowded, and the most busy, and we don?t give them space in the back room to check it well. I mean, they?re lucky sometimes that they don?t have to take those cartons, they?re strung out along the hallway for a couple of hours, as they?re working out sorting it and they can make as many mistakes checking it in as we make sending it to them.?

Finish Line takes a complete physical of the entire inventory, including the stores and the distribution center, twice a year. Generally, 15 to 20 stores are checked each week. These store counts are done either by visiting store managers or by an outside firm. The distribution center is shut down for a few days over a weekend to count inventory.

Performance Measures

The two primary performance measures used to evaluate the logistics system, are inventory turns and stockouts. Inventory turns is calculated as the cost of goods sold during a year divided by average inventory value. Both the cost of goods and the inventory value are calculated using the amount paid the vendor for each item. Currently, Finish Line turns their inventory a little more than two times per year.

It is difficult to get a true measure of lost sales due to not having inventory available. Stockouts are measured by an audit every night of each SKU at each store location. A stock out is recorded where the inventory level is zero. Average stock outs currently only run at about 3 percent of the SKU/location combinations.

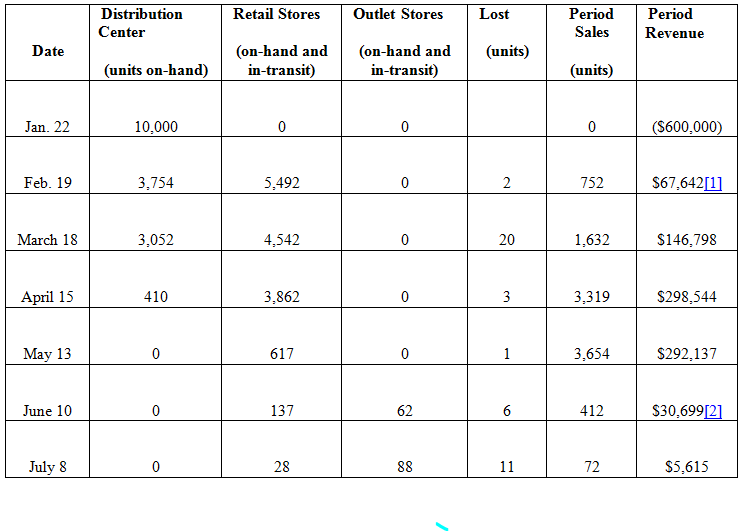

Date Jan. 22 Feb. 19 March 18 April 15 May 13 June 10 July 8 Distribution Center (units on-hand) 10,000 3,754 3,052 410 0 0 0 Retail Stores (on-hand and in-transit) 0 5,492 4,542 3,862 617 137 28 Outlet Stores (on-hand and in-transit) 0 0 0 0 0 62 88 Lost (units) 2 20 3 1 6 11 Period Period Sales Revenue (units) 0 752 1,632 3,319 3,654 412 72 ($600,000) $67,642[1] $146,798 $298,544 $292,137 $30,699[2] $5,615

Step by Step Solution

3.40 Rating (159 Votes )

There are 3 Steps involved in it

Step: 1

1 Manufacturing products is always a complicated business especially if the product is seasonal There are always elements that prevent the company from making as much as sales possible in some time of ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started