A company has two factories, one at Liverpool and one at Brighton.[20] In addition it has four depots with storage facilities at Newcastle, Birmingham, London

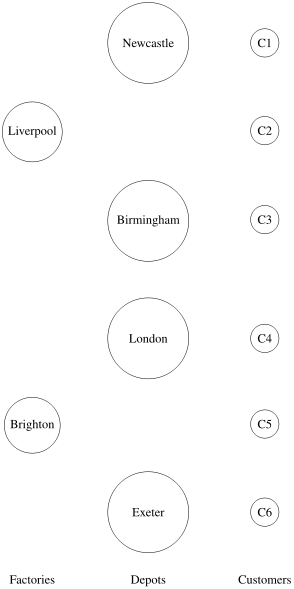

A company has two factories, one at Liverpool and one at Brighton.[20] In addition it has four depots with storage facilities at Newcastle, Birmingham, London and Exeter. The company sells its product to six customers C1, C2, ?, C6. Customers can be supplied either from a depot or from the factory direct (see Figure 19.1).

Figure 19.1:

Table 19.1:

| Supplier[a] | ||||||

| Liverpool | Brighton | Newcastle | Birmingham | London | Exeter | |

| Supplied to | factory | factory | depot | depot | depot | depot |

| Depots | ||||||

| Newcastle | 0.5 | ? | ||||

| Birmingham | 0.5 | 0.3 | ||||

| London | 1.0 | 0.5 | ||||

| Exeter | 0.2 | 0.2 | ||||

| Customers | ||||||

| C1 | 1.0 | 2.0 | ? | 1.0 | ? | ? |

| C2 | ? | ? | 1.5 | 0.5 | 1.5 | ? |

| C3 | 1.5 | ? | 0.5 | 0.5 | 2.0 | 0.2 |

| C4 | 2.0 | ? | 1.5 | 1.0 | ? | 1.5 |

| C5 | ? | ? | ? | 0.5 | 0.5 | 0.5 |

| C6 | 1.0 | ? | 1.0 | ? | 1.5 | 1.5 |

| [a] A dash indicates the impossibility of certain suppliers for certain depots or customers. | ||||||

The distribution costs (which are borne by the company) are known; they are given in Table 19.1 (in ? per ton delivered).

Certain customers have expressed preferences for being supplied from factories or depots which they are used to. The preferred suppliers are

| C1 | Liverpool (factory) |

| C2 | Newcastle (depot) |

| C3 | No preferences |

| C4 | No preferences |

| C5 | Birmingham (depot) |

| C6 | Exeter or London (depots) |

Each factory has a monthly capacity given below which cannot be exceeded:

| Liverpool | 150,000 tons |

| Brighton | 200,000 tons |

Each depot has a maximum monthly throughput given below which cannot be exceeded:

| Newcastle | 70,000 tons |

| Birmingham | 50,000 tons |

| London | 100,000 tons |

| Exeter | 40,000 tons |

Each customer has a monthly requirement given below which must be met:

| C1 | 50,000 tons |

| C2 | 10,000 tons |

| C3 | 40,000 tons |

| C4 | 35,000 tons |

| C5 | 60,000 tons |

| C6 | 20,000 tons |

The company would like to determine:

a- What distribution pattern would minimize overall cost?

b- What the effect of increasing factory and depot capacities would be on distribution costs?

c- What the effects of small changes in costs, capacities and requirements would be on the distribution pattern?

d- Would it be possible to meet all customers preferences regarding suppliers and if so what would the extra cost of doing this be?

Liverpool Brighton Factories Newcastle Birmingham London Exeter Depots C1 C2 C3 C4 C5 C6 Customers

Step by Step Solution

3.41 Rating (160 Votes )

There are 3 Steps involved in it

Step: 1

To solve this problem well apply a linear programming LP approach to optimize the distribution pattern considering costs capacities and preferences Le...

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started