Question

Natalie slowly walks down the hall after leaving Mr. Harnswell's office, feeling rather downcast. He just won't listen to anyone, she thinks. As she walks,

Natalie slowly walks down the hall after leaving Mr. Harnswell's office, feeling rather downcast. He just won't listen to anyone, she thinks. As she walks, Jim Murante, the shop foreman, comes up beside her. "So," he says, "did you really think that he would listen to you? I've been here more than 25 years. The only way he listens is if he is shown something that worked after it has already been done. Let's see what we can plan together".

Natalie and Jim decide to begin by investigating the production of the cam rollers, which are precision-ground parts.

The last part of the production process involves the grinding of the outer diameter. After grinding, the part mates with the cam groove of the particular sewing pattern. The half-inch rollers technically have an engineering specification for the outer diameter of the roller of 0.5075 inch (the specifications are actually metric, but in factory floor jargon, they are referred to as half-inch), plus a tolerable error of 0.0003 inch on the lower side. Thus, the outer diameter is allowed to be between 0.5072 and 0.5075 inch. Anything larger is reclassified into a different and less costly category, and anything smaller is unusable for anything other than scrap.

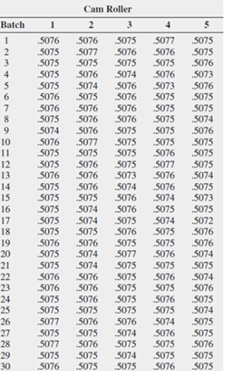

Table HS 14.1 Diameter of Cam Rollers (in inches)The grinding of the cam roller is done on a single machine with a single tool setup and no change in the grinding whet after initial setup. The operation is done by Dave Martin, the head machinist, who has 30 years of experience in the trade and specific experience producing the cam roller part. Because production occurs in batches, Natalie and Jim sample fl parts produced from each batch. Table HS14.1 presents data collected over 30 batches (stored in Harnswell)

a. Is the process in control? Why?

b. What recommendations do you have for improving the process?

Batch 1 1 5076 5076 5075 2 5075 5077 5076 3 5075 5075 5075 5075 5076 5075 5074 5076 5075 5076 5075 5 6 7 8 9 10 11 12 13 14 15 16 17 18 :*287232385828 19 20 21 24 26 29 30 5075 5075 .5076 5075 5075 5076 Cam Roller 2 5076 5076 5075 .5076 5076 5075 .5074 5076 5075 5075 5076 5077 5075 5075 5075 5075 5075 5076 5075 5076 5075 .5076 5075 5075 5075 5074 5075 5077 5075 5074 5075 5076 5076 5075 5077 5076 5073 5076 5074 5074 5076 5076 5074 5076 5073 5076 5075 5076 5075 5076 5075 5075 5077 5076 5075 5076 5075 5075 5074 5076 5075 5075 5077 5076 5075 5076 5074 5076 5076 5074 5076 5075 5075 5076 5075 5077 5075 5075 5075 5075 5075 5076 5074 5075 5075 5076 5075 5076 5075 5076 5075 5074 5074 5076 5075 5075 5076 5 5075 5075 5076 5073 5076 5075 5075 5074 5076 5075 5075 5075 5074 5075 5073 5075 5072 5076 5076 5074 5075 5074 5076 5075 5074 5075 5075 5076 5075 5075

Step by Step Solution

3.48 Rating (158 Votes )

There are 3 Steps involved in it

Step: 1

a To determine whether or not this process is statistically in control control charts will be created In order to construct control charts the range a...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Document Format ( 2 attachments)

60919cec52130_22472.pdf

180 KBs PDF File

60919cec52130_22472.docx

120 KBs Word File

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started